Howdy all,

First post. Need some opinions.

Short story - borderline money shifted my car, but caught it before over-rev. However, the shock load on the drivetrain was enough to break the tires loose in third. Both tires, courtesy of Wavetrac. A little while later, started hearing little clunks here and there, and eventually got bad enough that I decided to pull the trans for a failed DMFW. The flywheel is definitely toast, has about 3/16" axial play in the secondary mass.

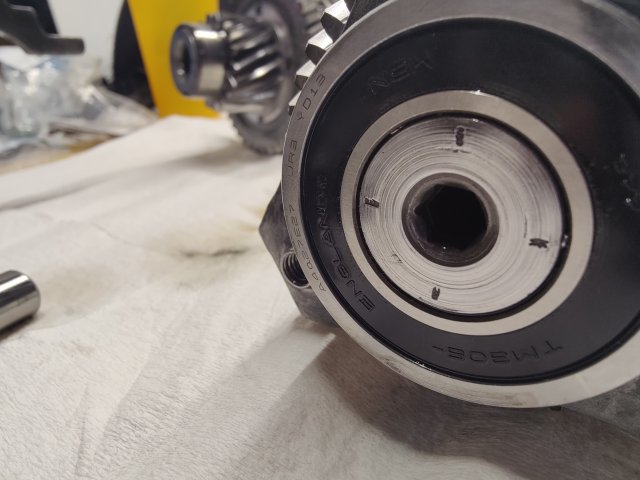

Saw some aluminum in the gear oil when draining, so I pulled the trans apart. What I found is that, apparently there was enough thrust load on the input shaft either due to the original impulse or driving a few thousand miles with a broken DMFW, that the big end of the shaft rubbed into the housing. Issue is, that bearing pocket has a little oil pump/slinger element in it, which is worn in roughly .005" where the shaft nut wore against it. The shaft nut was surprisingly worn as well - lots of little curly cues that look like steel turnings cut with a dull insert, on the magnet.

Has anyone seen similar and run the trans? Any issues if so?

It's not exactly a high performance pump, and its job looks like it's just to siphon a little bit of oil in from the sump and send it down the center of the shaft to the gear roller bearings. I'm inclined to maybe smooth it a little bit, clean everything out thoroughly and send it, but want to gather any and all experienced input.

Thanks!

First post. Need some opinions.

Short story - borderline money shifted my car, but caught it before over-rev. However, the shock load on the drivetrain was enough to break the tires loose in third. Both tires, courtesy of Wavetrac. A little while later, started hearing little clunks here and there, and eventually got bad enough that I decided to pull the trans for a failed DMFW. The flywheel is definitely toast, has about 3/16" axial play in the secondary mass.

Saw some aluminum in the gear oil when draining, so I pulled the trans apart. What I found is that, apparently there was enough thrust load on the input shaft either due to the original impulse or driving a few thousand miles with a broken DMFW, that the big end of the shaft rubbed into the housing. Issue is, that bearing pocket has a little oil pump/slinger element in it, which is worn in roughly .005" where the shaft nut wore against it. The shaft nut was surprisingly worn as well - lots of little curly cues that look like steel turnings cut with a dull insert, on the magnet.

Has anyone seen similar and run the trans? Any issues if so?

It's not exactly a high performance pump, and its job looks like it's just to siphon a little bit of oil in from the sump and send it down the center of the shaft to the gear roller bearings. I'm inclined to maybe smooth it a little bit, clean everything out thoroughly and send it, but want to gather any and all experienced input.

Thanks!

Attachments

-

8.2 MB Views: 8

-

5.1 MB Views: 7