-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

Really Should Stop Modifying my Daily Driver into a Track Car

- Thread starter Fusion Works

- Start date

Well, I got it in place and locked down. Yeah that was a pain in the ass. Wonder why its so far out of spec on the cable position? So far with no cable adjustment I have all gears, with the engine not running. That is a plus.

Thread Starter

#185

Thread Starter

#185

Yeah with everything bolted down tight, I have all gears and such with the car in neutral, not running me not holding the clutch pedal down. Haven't done any of the OEM centering adjustments yet.

To me the only major improvement I would make to this shifter assembly, is the adding an extension to the forward back bell crank to move the top ball stud closer to the center of the assmembly to straighten the overall angle of that linkage rod.

To me the only major improvement I would make to this shifter assembly, is the adding an extension to the forward back bell crank to move the top ball stud closer to the center of the assmembly to straighten the overall angle of that linkage rod.

Thread Starter

#192

Thread Starter

#192

Well this was an incredible pain in the ass and way more time than it should be.

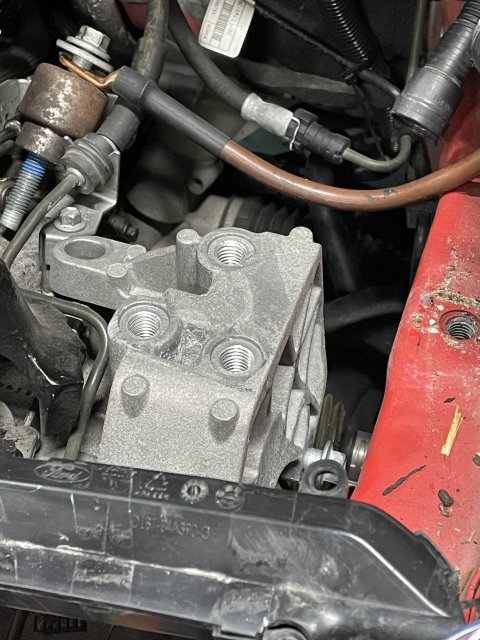

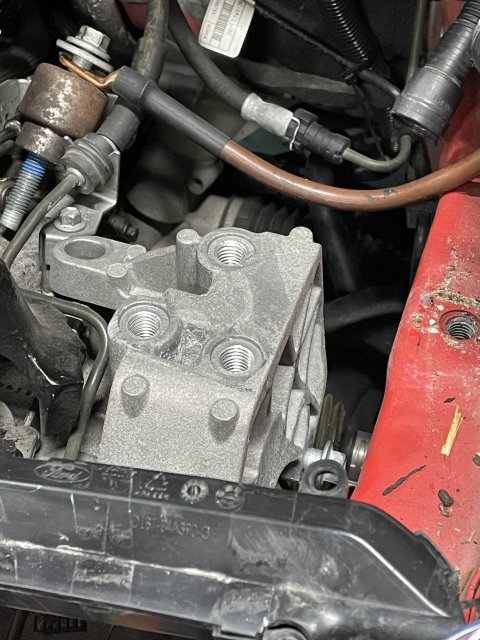

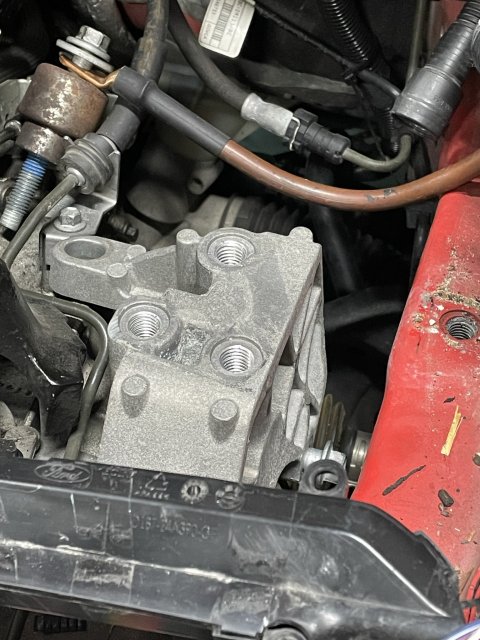

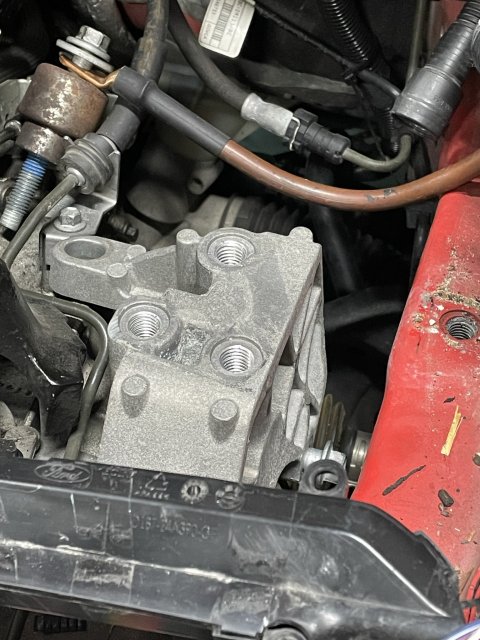

The trans mount studs are pressed in and crimped in place as far I can tell. Removing them was a massive pain. I will let ya’ll guess why I removed them.

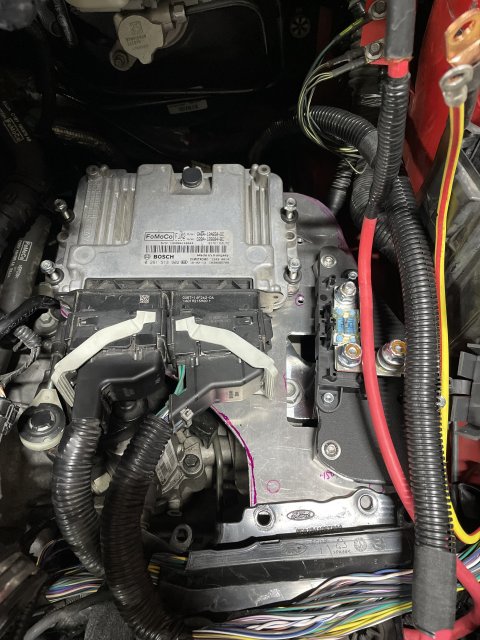

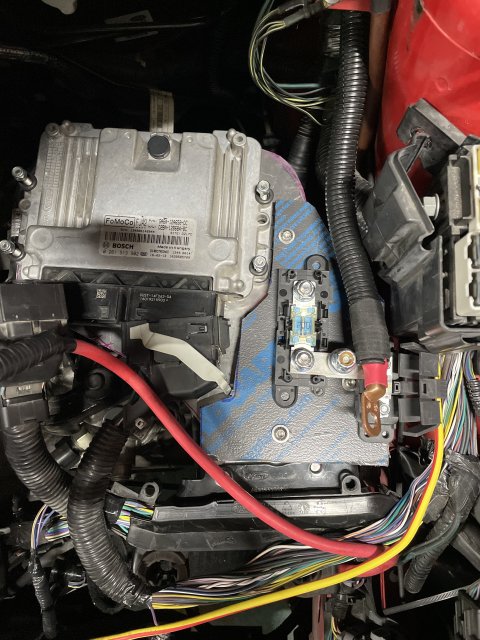

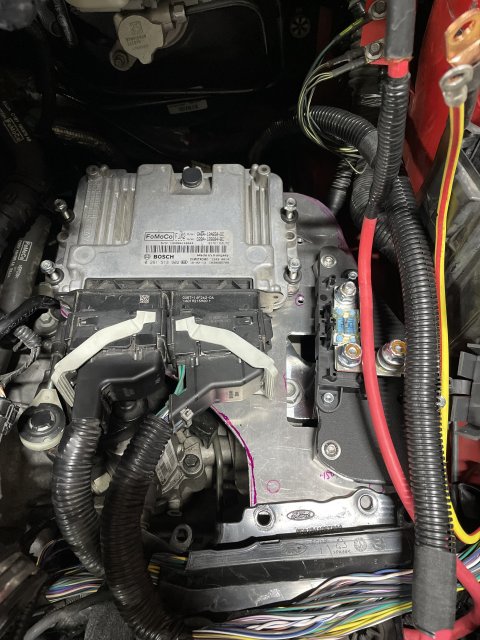

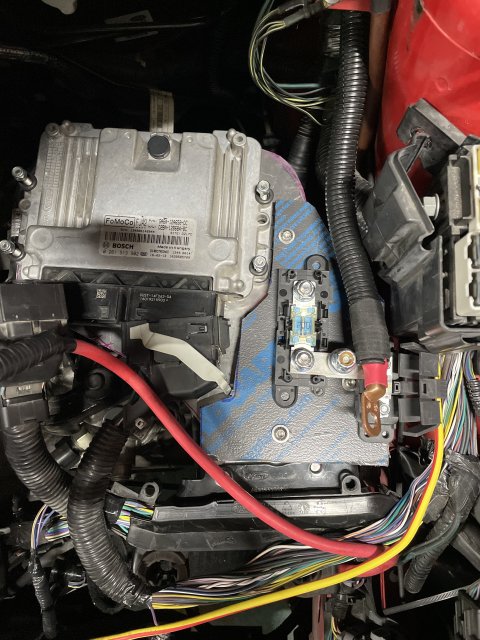

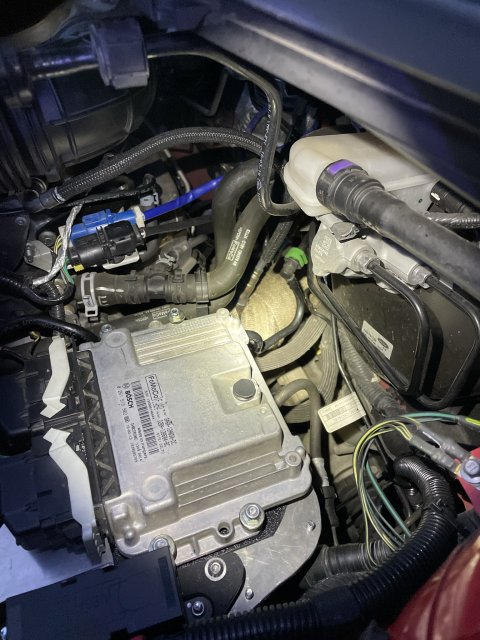

This is the final iteration of my ECU and fuse mounting plate is coming along. This will clean up all of the battery box area

The trans mount studs are pressed in and crimped in place as far I can tell. Removing them was a massive pain. I will let ya’ll guess why I removed them.

This is the final iteration of my ECU and fuse mounting plate is coming along. This will clean up all of the battery box area

Thread Starter

#194

Thread Starter

#194

Ok its been a busy while since I have updated this, but a lot of parts have been made in order to get the car on track for Gridlife.

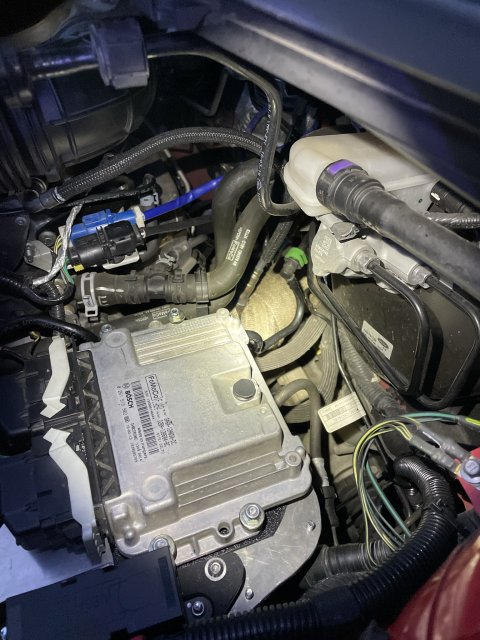

I mostly finished the battery relocation and wiring clean up in the engine bay. I need to run one wire to the back where the battery is to connect all the battery sensors directly to the battery for now they are just tied up in the engine bay not connected. However I have no check engine light because of it either.

I spent a ton of time on lowering the engine. It was a ridiculous amount of work for probably a minimal gain. I made custom 1in stainless spacer studs to go into the OEM transmission mount on the case. Removing those OEM studs was a massive pain in the ass, they are cast in place I think.

The studs are 17-4 stainless, cuz its stupid strong and I don't have to deal with zinc plating it. These in conjunction with some aluminum spacers and longer studs on the drivers side bracket worked out pretty well. I had to build a custom dog bone and change the angle on my down pipe to rotate it up into the tunnel, which I wanted to do anyways. Doing that cleaned up the exhaust I always felt hung down to far.

I mostly finished the battery relocation and wiring clean up in the engine bay. I need to run one wire to the back where the battery is to connect all the battery sensors directly to the battery for now they are just tied up in the engine bay not connected. However I have no check engine light because of it either.

I spent a ton of time on lowering the engine. It was a ridiculous amount of work for probably a minimal gain. I made custom 1in stainless spacer studs to go into the OEM transmission mount on the case. Removing those OEM studs was a massive pain in the ass, they are cast in place I think.

The studs are 17-4 stainless, cuz its stupid strong and I don't have to deal with zinc plating it. These in conjunction with some aluminum spacers and longer studs on the drivers side bracket worked out pretty well. I had to build a custom dog bone and change the angle on my down pipe to rotate it up into the tunnel, which I wanted to do anyways. Doing that cleaned up the exhaust I always felt hung down to far.

Thread Starter

#195

Thread Starter

#195

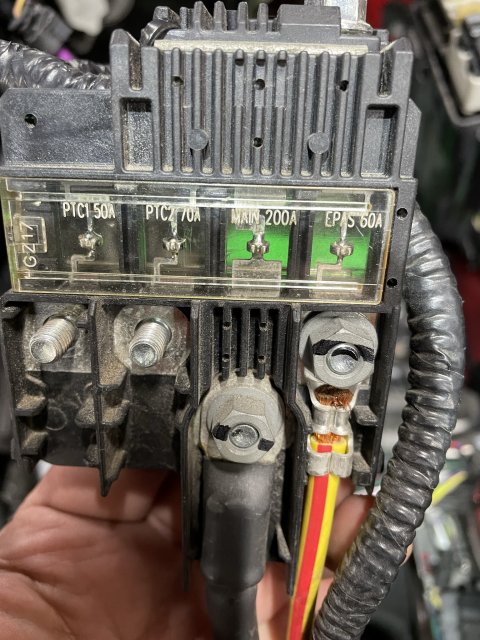

Some more pics of the electrical clean up:

There are still the proper fuses setup for the main fuse box and the power steering. I still need to attach the huge 450amp fuse at the battery, but I have never had an issue with the run from the front to the back so its not a huge priority.

The two little wires are the transponder wires that run up from the splitter where I have it mounted. They get connected to power and ground when I am running an event that has timing and scoring.

There are still the proper fuses setup for the main fuse box and the power steering. I still need to attach the huge 450amp fuse at the battery, but I have never had an issue with the run from the front to the back so its not a huge priority.

The two little wires are the transponder wires that run up from the splitter where I have it mounted. They get connected to power and ground when I am running an event that has timing and scoring.

Thread Starter

#196

Thread Starter

#196

Also built and installed all the proper safety equipment. Built the roll bar to SCCA regs, but its all Docol R8 tubing that was TIG welded with the proper filler material. Its bolt in, because I have a sunroof and I probably will have to remove the damn thing in the future to fix a water leak. I can also now get it powder coated. I welded plates to the floor with weld nuts behind them. Then bolt the roll bar to those plates. They tie into much stronger chassis points than the sheetmetal of the floor and the fender wells. I actually reused one of the rear seat anchor bolts along with the three other mounting bolts in the rear down legs. I haven't weighed it but its probably about 45lbs.

Thread Starter

#197

Thread Starter

#197

While building the roll bar, I made some lightweight seat mounts for the Racetech seat and Racequip harnesses. One thing I like about this seat are the proper holes for running a real six point harness the way it should be run. So many modern seats are actually designed for 5pt harnesses which aren't as safe in my opinion. These mounts weigh a third of what those stupid Planted seat bases weigh. The side mounts were some I designed for an RX8. They sorta worked here, but after being on track my butt was too low and I had to put a towel in the seat to get my eyes up above the wheel rim. I think I will add a hole to use a different style side plate to get my butt up a little higher for better visibility.

Similar threads

-

How critical is setting the preload really

- Started by unspankable

- Replies: 7

-

I'm in a spot of trouble, could really use some advice...

- Started by ORANGEST

- Replies: 4

-

How thin is the paint really?

- Started by BleehbleBlahble

- Replies: 10

-

Can’t figure out Really cool feature! How to change climate control via voice command

- Started by Stkid93

- Replies: 0

-

How much does brake rotor slot direction really matter?

- Started by Jabbit

- Replies: 9

-

Vega wing and risers really change the car

- Started by Whenchilling

- Replies: 11

-

Code P219a- really the 02 sensor, or something else?

- Started by mdirks

- Replies: 6

-

Best rotor pad combo for daily driver in really hot climate.

- Started by GreenenvyFiST

- Replies: 39

-

-