-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

Epoxy engine block mod

- Thread starter Scol

- Start date

Thread Starter

#4

I mean for backyard engineering it works, but epoxy and aluminum do not expand at the same rate and it will eventually cause issues... If I'm making big enough power to support the block I would just spend the cash on this

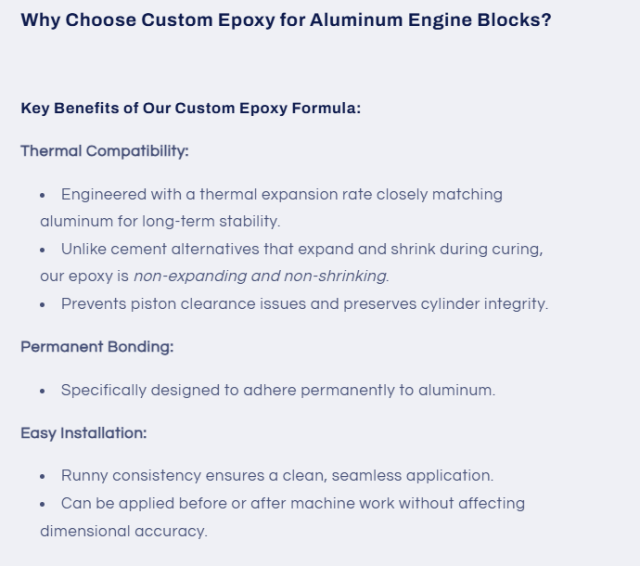

With regards to the expansion rate between materials, a seller of this epoxy (without mentioning names) claims the following :

Agreed 100%. For reliability long term, going for aluminium CNC inserts is the way to go. However i've read a few have used this for years on high boost applications without any issues. Hence why I am asking the question.

With regards to the expansion rate between materials, a seller of this epoxy (without mentioning names) claims the following :

View attachment 67806

With regards to the expansion rate between materials, a seller of this epoxy (without mentioning names) claims the following :

View attachment 67806

It sounds like a low expansion epoxy derived from the stuff used to fill uncooled engine blocks for drag racing.

Procedure seems to be to fill the engine block partially with sugar or salt, pour a bit of epoxy into the top to reinforce it, and rinse out the sugar/salt post cure.

Seems interesting but not without the hazards of any kind of custom modification. Holes need to be drilled to allow coolant to flow to and from the head.

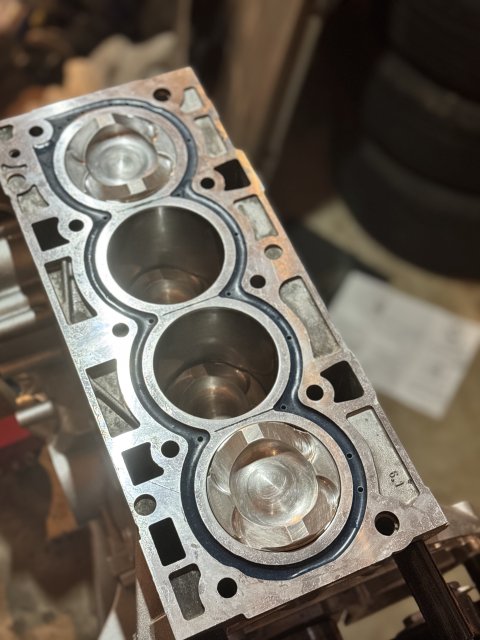

There’s even a photo here of a block like ours (with thin slots between cylinders) filled this way

https://epoxy54.com/products/epoxy54?

Procedure seems to be to fill the engine block partially with sugar or salt, pour a bit of epoxy into the top to reinforce it, and rinse out the sugar/salt post cure.

Seems interesting but not without the hazards of any kind of custom modification. Holes need to be drilled to allow coolant to flow to and from the head.

There’s even a photo here of a block like ours (with thin slots between cylinders) filled this way

https://epoxy54.com/products/epoxy54?

Thread Starter

#8

I used the eBay kit and it works flawlessly, over 4000 miles on the motor so far no issues. I have a very upgraded cooling system so my temps probably will different then others. I have a koyo rad, deleted all of the coolant bypass systems using the oem base model ford fiesta thermostat housing and a custom water distribution block I designed. I use a 180 degree thermostat and it stays roughly 160-180 on the highway cruising. It fluctuates obviously when I’m ripping on it but I’ve never had it over 190. I’ve driven the car in 90+ degree weather and have driven it for entire days and I dailied it for a while no issues. You wouldn’t be able to tell it has epoxy and fully forged pistons and rods. If anyone has questions don’t hesitate to ask. I was considering making full write ups for everything I’ve done. Especially the fuse box swap from 2014 to 2016+

Attachments

-

6.2 MB Views: 10

-

2 MB Views: 16

Similar threads

-

-

-

-

Heavy Coolant Leak from Backside of Engine

- Started by turbolag277

- Replies: 3

-

-

SLD SOLD SOLD 2014 Ingot Silver Fiesta ST 56k miles with 2016 engine + cobb AP and tune $9,000 - OBO IE SOCAL

- Started by ray02945

- Replies: 7

-

-

-

New product 🚨 Gradient Engineering Intake Manifold

- Started by Focused

- Replies: 1

-

New Engine mount rattle/knock noise

- Started by Fretzy

- Replies: 1