Hey guys I’m at the point I really need to figure out what has happened to my ST.

Short story. I finished my build and went easy on it until break in point of changing oil at just under 1000 miles. Pulled the plug and it looks like a golden dust storm took place in the motor.

I started working on the car in late December. I replaced just about every part that a bolt-on car could have.

Thermal exhaust w/ 3 adapter

Whoosh V3 ic

Mountune radiator

Whoosh piping

TT S280 w/ turbosmart wastegate

Vibra-technics trans and motor mount

Whoosh short shift kit

Oem Hpfp cam bucket

Xtreme Di hpfp

Dizzy map sensor

Bosch uprated injectors

Turbosmart em bov

Whoosh catless dp

AP racing st200 clutch kit

Oem slave cylinder

Tuned on E50

Move to the first week of January and the car was ready to start. Drove fine, at this point I’m driving it like it’s a million dollar car. Getting the clutch mated to the flywheel and overall letting all the new parts settle and see if anything is amiss. I get to the 500 mile mark before I get my first revision of the tune uploaded. At this point I’m surprised nothing has shown up. Everything is on point and the car is driving exactly has you’d hope it would. (Let me say as I write this the car has been sitting for some time now, so I’m going off memory) it was about the 700 mile mark I began to hear a noise. Nothing crazy. And I was only able to hear it under certain circumstances. In gear, with no throttle coasting down a hill letting the rpm’s rise to between 2500-3000 I was getting a tick, almost like a injector ticks. The injectors will shut off at this point. So I ruled them out. And the xtreme hpfp has a very distinct sound. So ruled that out as well.

just over 900 miles in on the build, I decided to change the oil. And from that point, it has stopped me in my tracks. After seeing what looked like golden dust in the oil I started pulling the easiest parts that would hopefully give me insight of the issue. Valve cover, oil pan and intake. Turbo... zero play. Cam lobes, also good. Oil pan, nothing in the bottom. I did pull connecting rod caps, but that’s the only bearings I’ve checked. They checked out. Nothing with a bearing shows signs of overheating. And I feel at this point any bearing from here will escalate to other parts needing removed to gain access.

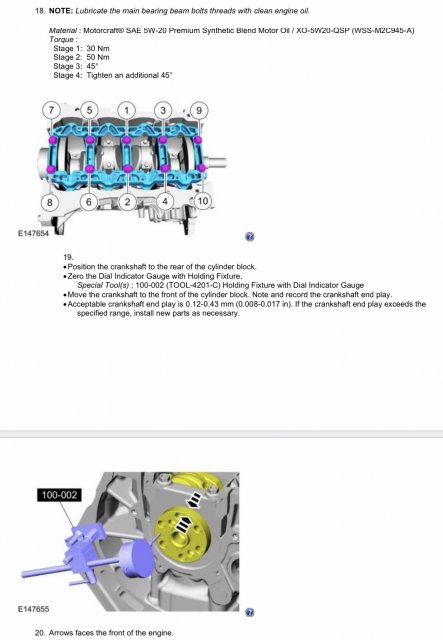

I got to the thrust bearing. And this is where I focused in. I’ve checked All-Data and tried my best to use a dial indicator. With no definitive proof of a reading I would trust.

Has anyone else come across this issue on these motors? Or am I looking in the wrong place? Could ethanol getting in make a similar colored cascade effect in the oil? Unfortunately I never snapped a shot of the oil, and I drained it in a tank of already used oil. So lab testing could been altered. Mistakes were made.

I do have a short clip I looped of what shows me pressing in and out of the clutch pedal and the effect it has on the crank.

Thanks for taking the time to read a long winded story of what looks like a long road for me.

Short story. I finished my build and went easy on it until break in point of changing oil at just under 1000 miles. Pulled the plug and it looks like a golden dust storm took place in the motor.

I started working on the car in late December. I replaced just about every part that a bolt-on car could have.

Thermal exhaust w/ 3 adapter

Whoosh V3 ic

Mountune radiator

Whoosh piping

TT S280 w/ turbosmart wastegate

Vibra-technics trans and motor mount

Whoosh short shift kit

Oem Hpfp cam bucket

Xtreme Di hpfp

Dizzy map sensor

Bosch uprated injectors

Turbosmart em bov

Whoosh catless dp

AP racing st200 clutch kit

Oem slave cylinder

Tuned on E50

Move to the first week of January and the car was ready to start. Drove fine, at this point I’m driving it like it’s a million dollar car. Getting the clutch mated to the flywheel and overall letting all the new parts settle and see if anything is amiss. I get to the 500 mile mark before I get my first revision of the tune uploaded. At this point I’m surprised nothing has shown up. Everything is on point and the car is driving exactly has you’d hope it would. (Let me say as I write this the car has been sitting for some time now, so I’m going off memory) it was about the 700 mile mark I began to hear a noise. Nothing crazy. And I was only able to hear it under certain circumstances. In gear, with no throttle coasting down a hill letting the rpm’s rise to between 2500-3000 I was getting a tick, almost like a injector ticks. The injectors will shut off at this point. So I ruled them out. And the xtreme hpfp has a very distinct sound. So ruled that out as well.

just over 900 miles in on the build, I decided to change the oil. And from that point, it has stopped me in my tracks. After seeing what looked like golden dust in the oil I started pulling the easiest parts that would hopefully give me insight of the issue. Valve cover, oil pan and intake. Turbo... zero play. Cam lobes, also good. Oil pan, nothing in the bottom. I did pull connecting rod caps, but that’s the only bearings I’ve checked. They checked out. Nothing with a bearing shows signs of overheating. And I feel at this point any bearing from here will escalate to other parts needing removed to gain access.

I got to the thrust bearing. And this is where I focused in. I’ve checked All-Data and tried my best to use a dial indicator. With no definitive proof of a reading I would trust.

Has anyone else come across this issue on these motors? Or am I looking in the wrong place? Could ethanol getting in make a similar colored cascade effect in the oil? Unfortunately I never snapped a shot of the oil, and I drained it in a tank of already used oil. So lab testing could been altered. Mistakes were made.

I do have a short clip I looped of what shows me pressing in and out of the clutch pedal and the effect it has on the crank.

Thanks for taking the time to read a long winded story of what looks like a long road for me.

Last edited: