Hi guys!

I'm replacing the timing belt on my 1.6 Ecoboost and I'm wondering what the purpose of the pulley alignment tool is. I thought it was perhaps to relieve stress while tightening the crankshaft bolt, but the workshop manual says to remove it before tightening. Is it related to balancing? Does anybody know?

I'm replacing the timing belt on my 1.6 Ecoboost and I'm wondering what the purpose of the pulley alignment tool is. I thought it was perhaps to relieve stress while tightening the crankshaft bolt, but the workshop manual says to remove it before tightening. Is it related to balancing? Does anybody know?

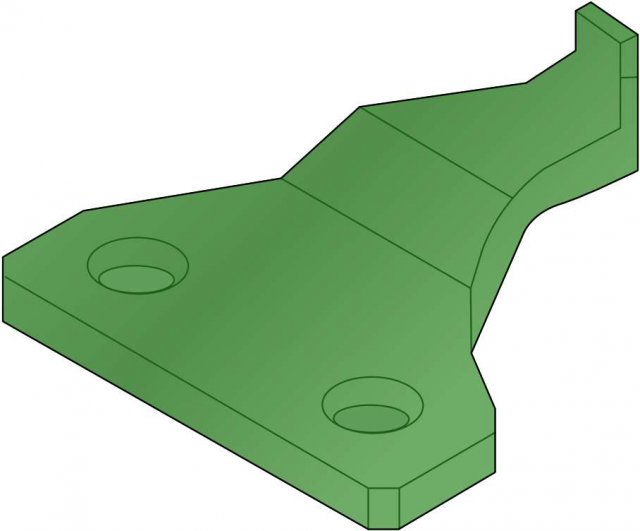

Attachments

-

26.1 KB Views: 14