So I have finally located a set of high-strength Class 12.9 bolts, nuts and locking washers that can replace the factory "disposable" stretch bolts that are used for attaching the front struts to the hub at the bottom.

Because I had to buy a whole batch and have them shipped from Australia at significant expense in order to source them, I have a limited number of extra sets that I'm offering up for sale to recoup some of the cost. Yes, the date on the photo is from June, but for safety reasons, I decided to wait until I had actually installed and tested driving with them on the car before offering them to other people.

All items have the correct corrosion resistant Zinc Flake Coating (Aka Dacromet/Geomet/Delta-Protekt) just like the factory bolts, which means they will last just as well or better than the factory bolts, and won't rust or corrode like standard zinc or zinc chromate plated fasteners.

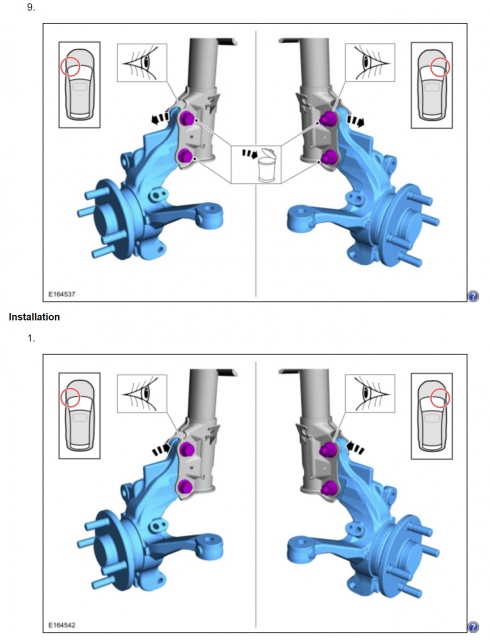

Bolts are a bit long (80mm), so they need to be installed with the heads towards the front of the car on both sides so the extended threads don't touch the the brake lines. The alternative was 55mm, which was a smidge too short with the lockwashers. The factory bolts oddly specify that the bolts on right and left of the car are installed differently, but this is not a problem, nor are the fact they are fully threaded (strut mount is a clamp joint so that alignment does not shift and the bolt is not loaded in shear). Do not cut the bolts short or you will compromise the corrosion resistant coating.

Because the nuts are not locking, I have included Nord-Lock washers (two sets per bolt), which are not only superior to nyloc or deformed thread when it comes to vibration and are rated for use with Class 12 bolts, they are also infinitely reusable (where most locknuts are limited use), so you can swap out front struts to your heart's content. One washer set is installed under the head and one under the nut to prevent rotation or loss of preload. Do not separate the washer sets or install them inverted (the wide ramp faces touch eachother, while the narrow serrated faces go against bolt and strut flange. They come lightly glued together but halves may separate after removal which is not a problem as long as you stack them back together correctly.

One set for both front struts consists of the following:

4x - Class 12.9 Flanged Hex Bolts, M12x1.75 80mm long, fully threaded

4x - Class 12 Flanged Nuts, M12x1.75

8x - Nord-Lock Washers, M12

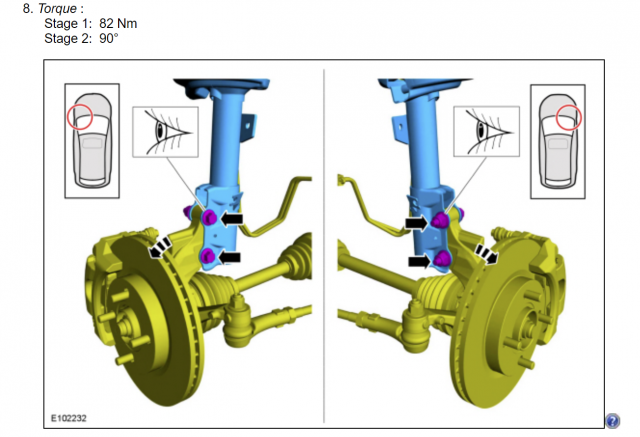

I highly recommend using antiseize (I prefer Loctite 8023 Marine Grade Antiseize). The correct calculated torque for these bolts (when lubricated with Antiseize) is 150 Nm (110 ft-lbs). Do not apply the factory torque method (torque+angle) or you will permanently damage the bolts and not be able to reuse them.

Cost is $75/set (shipping and paypal fee are included) Post here and PM me if you are interested, payment through Paypal

Because I had to buy a whole batch and have them shipped from Australia at significant expense in order to source them, I have a limited number of extra sets that I'm offering up for sale to recoup some of the cost. Yes, the date on the photo is from June, but for safety reasons, I decided to wait until I had actually installed and tested driving with them on the car before offering them to other people.

All items have the correct corrosion resistant Zinc Flake Coating (Aka Dacromet/Geomet/Delta-Protekt) just like the factory bolts, which means they will last just as well or better than the factory bolts, and won't rust or corrode like standard zinc or zinc chromate plated fasteners.

Bolts are a bit long (80mm), so they need to be installed with the heads towards the front of the car on both sides so the extended threads don't touch the the brake lines. The alternative was 55mm, which was a smidge too short with the lockwashers. The factory bolts oddly specify that the bolts on right and left of the car are installed differently, but this is not a problem, nor are the fact they are fully threaded (strut mount is a clamp joint so that alignment does not shift and the bolt is not loaded in shear). Do not cut the bolts short or you will compromise the corrosion resistant coating.

Because the nuts are not locking, I have included Nord-Lock washers (two sets per bolt), which are not only superior to nyloc or deformed thread when it comes to vibration and are rated for use with Class 12 bolts, they are also infinitely reusable (where most locknuts are limited use), so you can swap out front struts to your heart's content. One washer set is installed under the head and one under the nut to prevent rotation or loss of preload. Do not separate the washer sets or install them inverted (the wide ramp faces touch eachother, while the narrow serrated faces go against bolt and strut flange. They come lightly glued together but halves may separate after removal which is not a problem as long as you stack them back together correctly.

One set for both front struts consists of the following:

4x - Class 12.9 Flanged Hex Bolts, M12x1.75 80mm long, fully threaded

4x - Class 12 Flanged Nuts, M12x1.75

8x - Nord-Lock Washers, M12

I highly recommend using antiseize (I prefer Loctite 8023 Marine Grade Antiseize). The correct calculated torque for these bolts (when lubricated with Antiseize) is 150 Nm (110 ft-lbs). Do not apply the factory torque method (torque+angle) or you will permanently damage the bolts and not be able to reuse them.

Cost is $75/set (shipping and paypal fee are included) Post here and PM me if you are interested, payment through Paypal

Attachments

-

1.5 MB Views: 21

-

1.7 MB Views: 20

-

1.6 MB Views: 47

-

1.8 MB Views: 50

-

1.7 MB Views: 50

Last edited: