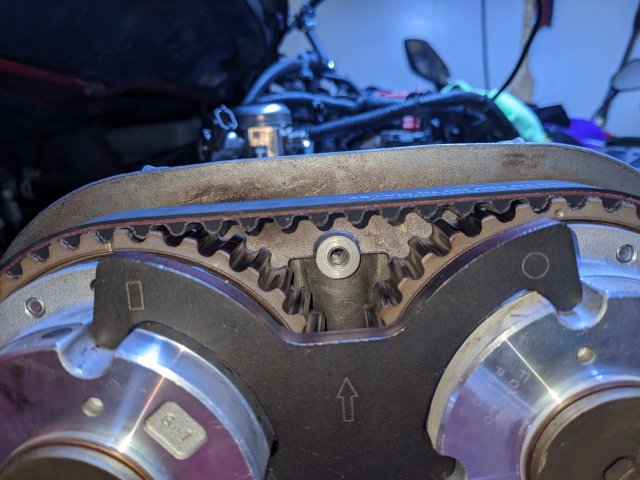

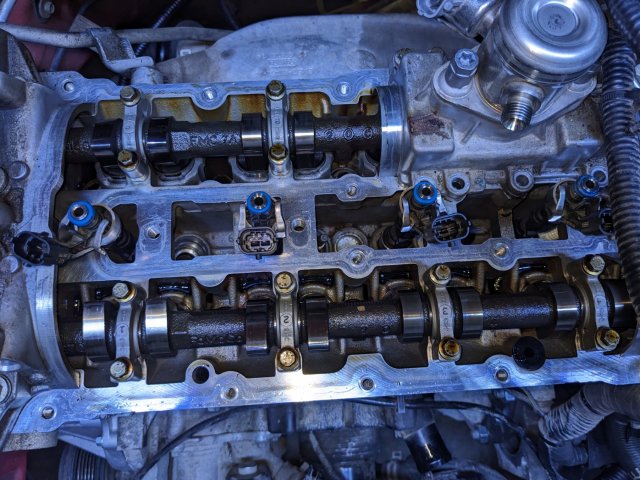

Must have messed something up last time because the cams were slightly off. Need to make sure its right this time so I can do a compression test. It's at TDC with the cam, flywheel and crank locking tools in place. Does this all look correct before I put it back together?

Attachments

-

1 MB Views: 35

-

1.2 MB Views: 35

-

1.1 MB Views: 38

-

1.2 MB Views: 35