-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

size of rear seat bracket/seat belt retainer bolts

- Thread starter M-Sport fan

- Start date

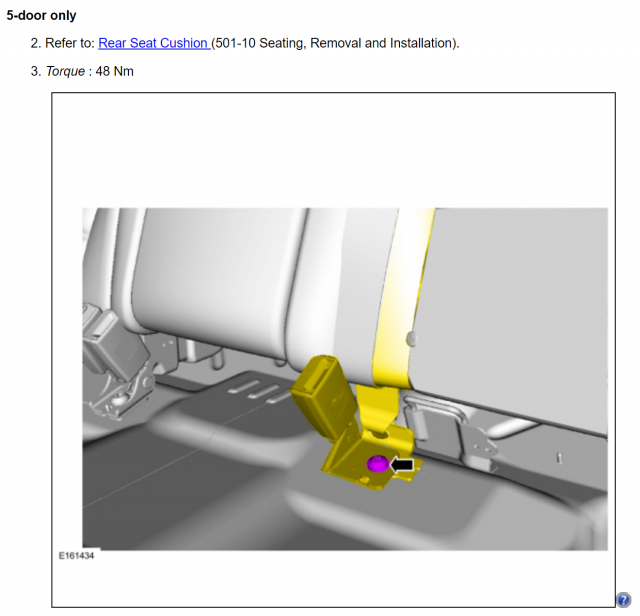

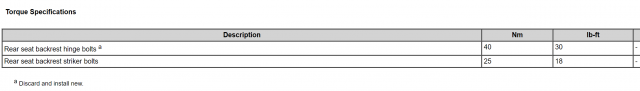

Are you talking about these guys (seatbelt or the rear hinge bolts)? If they are M10, 1.5mm pitch is the most common - ford doesn't seem to use many fine thread bolts.

Based on typical metric bolt torque values, they have to be at least Class 8.8. If they are M12, they’d be ~Class 5.6.

They are unlikely to be Class 12.9 M8's that would be safe at that kind of torque value.

Based on typical metric bolt torque values, they have to be at least Class 8.8. If they are M12, they’d be ~Class 5.6.

They are unlikely to be Class 12.9 M8's that would be safe at that kind of torque value.

Attachments

-

353.1 KB Views: 11

-

33.9 KB Views: 10

Last edited:

Thread Starter

#3

Thread Starter

#3

Yes, those are the ones, and I am surprised that Ford did not use a fine threaded bolt there, given how much more resistant they are to vibration induced loosening over time, on a seat and seatbelt mounting fastener.

But anyway, I did find some 18/8 stainless Torx button head (vs. the factory OEM whatever grade steel panhead ones) on McMaster-Carr.

Given the way everything rusts on these cars, I wanted somethin more corrosion-proof than the factory bolts to attach my Swave/Summit trunk brace on it's way from Ron.

And YES, I know that any stainless is not going to be as strong as (as well as being decidedly more 'brittle' than) even an 8.8 grade steel, but given it is not a life dependent application, I figured the 100K PSI tensile strength to be sufficient in this case.

(IF they would have offered a higher strength [130K PSI] stainless option like they do for other sizes in this bolt [or even in a flanged hex head bolt], I would have chosen that.![Wink [wink] [wink]](/images/smilies/wink.gif) )

)

But anyway, I did find some 18/8 stainless Torx button head (vs. the factory OEM whatever grade steel panhead ones) on McMaster-Carr.

Given the way everything rusts on these cars, I wanted somethin more corrosion-proof than the factory bolts to attach my Swave/Summit trunk brace on it's way from Ron.

And YES, I know that any stainless is not going to be as strong as (as well as being decidedly more 'brittle' than) even an 8.8 grade steel, but given it is not a life dependent application, I figured the 100K PSI tensile strength to be sufficient in this case.

(IF they would have offered a higher strength [130K PSI] stainless option like they do for other sizes in this bolt [or even in a flanged hex head bolt], I would have chosen that.

![Wink [wink] [wink]](/images/smilies/wink.gif) )

)Class 8.8 is rated at 800 MPa (116ksi) tensile, so 100ksi 18-8 is not far off. Safe torque for an A2 metric stainless (aka 18-8 or 304) in M10 would be 32 ft-lb. The full 40 ft-lb will yield them (stainless yield strength is lower than you'd expect).

If you want higher strength stainless, your options are either ARP stainless, A286, or 17-4PH. In general, pan heads and flat head fasteners kind of suck compared with hex and socket head cap except where you absolutely have to.

FYI, don't use 18-8 (304) externally if you will encounter road salt or you live in a coastal area - its very good against oxidation, but salts will cause pitting. For the trunk brace inside the car its probably okay.

Zinc Flake over steel (not to be confused with galvanized or normal zinc plate) is what is on all the OEM high strength fasteners and is the best option if you can find it. Zinc Flake is also known as Dacromet or Geomet trade names - same stuff used on brake rotors.

Barring that, 316 does decently or A286 stainless if you don't mind the cost. Yellow zinc dichromate does a little bit better than plain zinc plate.

If you want higher strength stainless, your options are either ARP stainless, A286, or 17-4PH. In general, pan heads and flat head fasteners kind of suck compared with hex and socket head cap except where you absolutely have to.

FYI, don't use 18-8 (304) externally if you will encounter road salt or you live in a coastal area - its very good against oxidation, but salts will cause pitting. For the trunk brace inside the car its probably okay.

Zinc Flake over steel (not to be confused with galvanized or normal zinc plate) is what is on all the OEM high strength fasteners and is the best option if you can find it. Zinc Flake is also known as Dacromet or Geomet trade names - same stuff used on brake rotors.

Barring that, 316 does decently or A286 stainless if you don't mind the cost. Yellow zinc dichromate does a little bit better than plain zinc plate.

Thread Starter

#6

Thread Starter

#6

McMaster-Carr did have fully threaded, M10x1.5, 40mm long, zinc dichromate 12.9 steel 17mm hex, hex head bolts, which I was going to order due to their 170K PSI rating.

I still may if I can find matching washers big enough to prevent the hex corners from digging into the (not sure what grade/Rockwell aluminum) alloy end mounts of the Swave brace due here tomorrow.

I will look at the brace end mounts tomorrow and see if there is enough room around the bolt holes for some 30mm washers to use under hex head bolts.

(Why I was drawn to the round shaped head, stainless Torx bolts I got, along with slightly larger Bumax 88 washers to help spread out that torque load over a greater area, and prevent that bolt top from digging into/'cold-forming' said alloy side mount.![Wink [wink] [wink]](/images/smilies/wink.gif) )

)

I did not see any; A286, 17-4PH, or zinc flake high(er) strength bolts, nor any flanged bolts I could use due to them not even offering some of them in ANY metric sizes at all, let alone in the one specific for this application, on McMaster-Carr's site.

They did have a Bumax 88 material option in this size, rated for 110K PSI, and supposedly more corrosion resistant than 316 stainless.

Maybe I should have gone for those?![Dunno [dunno] [dunno]](/images/smilies/icon_smile_dunno.gif)

I still may if I can find matching washers big enough to prevent the hex corners from digging into the (not sure what grade/Rockwell aluminum) alloy end mounts of the Swave brace due here tomorrow.

I will look at the brace end mounts tomorrow and see if there is enough room around the bolt holes for some 30mm washers to use under hex head bolts.

(Why I was drawn to the round shaped head, stainless Torx bolts I got, along with slightly larger Bumax 88 washers to help spread out that torque load over a greater area, and prevent that bolt top from digging into/'cold-forming' said alloy side mount.

![Wink [wink] [wink]](/images/smilies/wink.gif) )

)I did not see any; A286, 17-4PH, or zinc flake high(er) strength bolts, nor any flanged bolts I could use due to them not even offering some of them in ANY metric sizes at all, let alone in the one specific for this application, on McMaster-Carr's site.

They did have a Bumax 88 material option in this size, rated for 110K PSI, and supposedly more corrosion resistant than 316 stainless.

Maybe I should have gone for those?

Thread Starter

#8

Thread Starter

#8

If you’re really having a hard time finding washers, look around at 3/8” washers as well - some of them have a large enough ID to work with an M10 (and sometimes they’re sold as both with a different label on the bag)

Thread Starter

#9

Thread Starter

#9

Just for future reference for anyone else;

The Swave/Summit trunk brace uses STEEL end mounting plates, which are countersunk with a fairly small diameter pocket, so one would NOT be able to use a 17mm head bolt there, as even a thin wall 17mm socket would not be able to fit into that pocket.

Probably why they supply some 14mm hex head, zinc chromate coated, unknown strength (not labeled) serrated flange, M10 1.5 bolts with the bar.![Wink [wink] [wink]](/images/smilies/wink.gif)

(I might order, and try some 15mm hex head, 10.9 strength, serrated flange bolts just to see if they could fit using a 15mm socket.)

The Swave/Summit trunk brace uses STEEL end mounting plates, which are countersunk with a fairly small diameter pocket, so one would NOT be able to use a 17mm head bolt there, as even a thin wall 17mm socket would not be able to fit into that pocket.

Probably why they supply some 14mm hex head, zinc chromate coated, unknown strength (not labeled) serrated flange, M10 1.5 bolts with the bar.

![Wink [wink] [wink]](/images/smilies/wink.gif)

(I might order, and try some 15mm hex head, 10.9 strength, serrated flange bolts just to see if they could fit using a 15mm socket.)

Last edited:

Similar threads

-

-

-

-

-

-

Starting to Think about a Race Car Sized Rear Sway Bar

- Started by Fusion Works

- Replies: 52

-

-

-

-

Rear Motor Moubt bolt sizes?

- Started by ballinst

- Replies: 7