All,

Didn't see a post for this, so I decided to document my install.

First, used some spacers to take some of the wobble out of the bar. I know the clamp force is what drives the coupling, and there is no loading in shear... but the difference in the diameter of the bolt and the tube of the bar is bugging me.

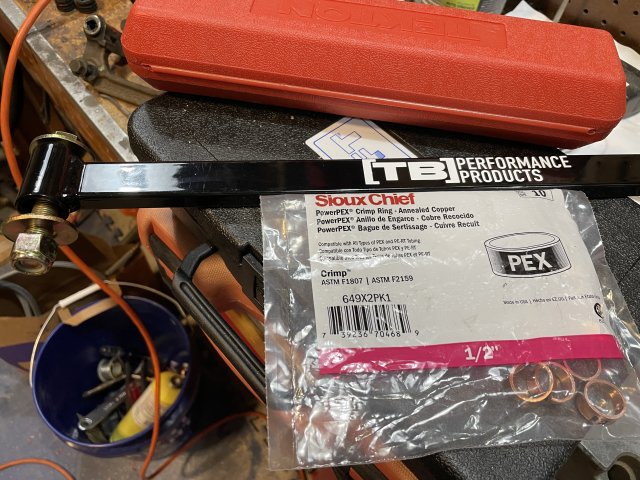

For those that are interested, 1/2" copper PEX crimp rings and 1/2" tube fit perfectly and take the majority of the slop out.

Didn't see a post for this, so I decided to document my install.

First, used some spacers to take some of the wobble out of the bar. I know the clamp force is what drives the coupling, and there is no loading in shear... but the difference in the diameter of the bolt and the tube of the bar is bugging me.

For those that are interested, 1/2" copper PEX crimp rings and 1/2" tube fit perfectly and take the majority of the slop out.

Attachments

-

5.1 MB Views: 48

-

1.9 MB Views: 46

-

1.4 MB Views: 37

-

1.4 MB Views: 47