Back in May we published our findings of data logging factory and Speed Engineering directionally vaned brake rotors. The testing was done in a controlled environment at the 21 turn Inde Motorsport Ranch in Wilcox, AZ. Testing was performed using an onboard infrared sensor and controller data logged against vehicle speed using the AEM EMS to verify braking speeds matched between testing of the factory and Speed rotors. Brake pads used were Carbotech XP10/XP8 and the fluid used was Motul RBF600.

more about the testing can be found at the original post here:

https://www.s2ki.com/s2000/topic/867...-brake-rotors/

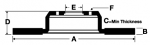

The testing showed the directionally vaned rotors, which are more efficient in cooling due to the pumping effect of air through the rotor were able to shed heat faster and trend cooler than the straight vaned factory rotors - running an average of nearly 60 deg F cooler and nearly 100 deg F cooler over a 22 turn lap. The question then became - what is the long term effect of the use?

long term update

Previously, our NASA TT-B prepped S2000 had rotor failure (a complete crack running through the rotor) within 5 days of track use using a new set of factory rotors. A "day" typically includes four 20 minute timed sessions. The factory rotors were used with the same type of Carbotech brake pads that we use today. These pads generate high friction and high heat to go along with it. In addition, the brake pads typically were good for 10 days using factory rotors. Since May's testing, we promised to report on long term durability testing. Using a new set of Speed Engineering rotors and Carbotech XP10/XP8 brake pads - we have since logged 13 days of track use. These 13 days included the same tracks driven in the 5 days with the factory rotor - so the testing is quite comparable.

After 13 track days, the rotors are still in fine condition with signs of only microscopic fractures. We estimate that they will be good for another 2-4 days. In addition to the increased rotor life, we have also seen about a 20-30% increase in pad life. Also, the brake fade we would typically experience with the factory rotors has now not been experienced since the installation of the rotors.

We've been very happy with the results, and hope you enjoy the data provided. With the cost of the Speed Engineering rotors being only slightly more than generic aftermarket brake discs, and less expensive than factory rotors and aftermarket slotted rotors - the Speed Engineering rotors seem like an obvious choice regardless of the use being for street or track use. In addition to the rotors, we can't help but be absolutely thrilled with the brake pad selection. We have managed over the past 10 years with the S2000 to try more than a dozen brake pad compounds. The Carbotech line of pads, especially the XP10/8 combination has proven to be the best performing and most rotor friendly combination we have ever tried. The brakes are now one aspect of the car that we have absolutely no complaints about.

more info on Speed Engineering directional brake rotors:

http://www.scienceofspeed.com/produc.../brake_rotors/

more info on Carbotech brake pads:

http://www.scienceofspeed.com/produc...000/Carbotech/

Should you have any questions, please don't hesitate to drop us a line.

cheers,

-- Chris

General Manager

ScienceofSpeed, LLC

ScienceofSpeed is offline

![Frown [:(] [:(]](/images/smilies/frown.png)

![Wink [wink] [wink]](/images/smilies/wink.gif)