-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

2860 install

- Thread starter SpiceyorangeST

- Start date

Thread Starter

#56

Thread Starter

#56

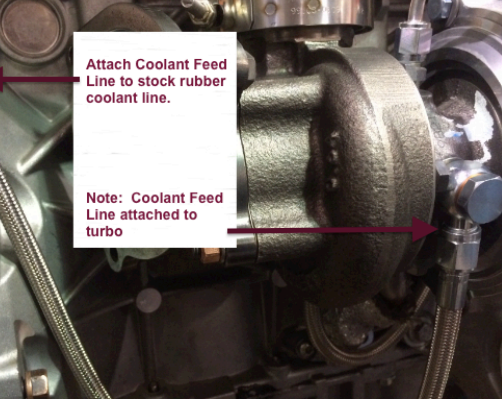

Align it at a right angle perpendicular to the ground. The braided line should point straight down when the turbo is mounted on the car.

View attachment 41455

View attachment 41455

So turbo is in. But looks like I should have mocked up this elbow for the charge pipe before I put the boost tap in because it's way too long and rubs against the rack, doesn't line up with where the charge pipe needs to be at all.

View attachment 41676

Sent from my SM-N975U1 using Tapatalk

Similar threads

-

-

-

-

mtune short block + v1 cams + gtx2860r dyno results

- Started by pwnall1337

- Replies: 3

-

-

-

-

Not making boost after 2860 install

- Started by dhminer

- Replies: 29

-

2860R turbo/ boost oscilating with 2.5" 2J?

- Started by jlbet1995

- Replies: 1

-

How To: Tial MVI 2.5 Wastegate Actuator install on GTX2860R

- Started by flip314

- Replies: 29

Ford Community Posts

-

-

My First ST with Mods 97K and I'm learning what I bought... The drive home was amazing!

- Latest: Stubborn Approach

-

-