There was a thread on this topic that was very helpful, but it disappeared.

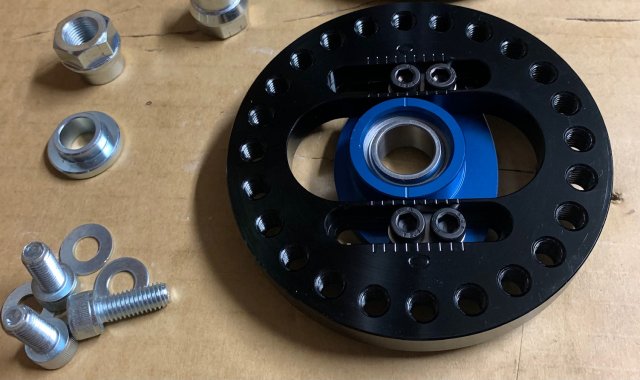

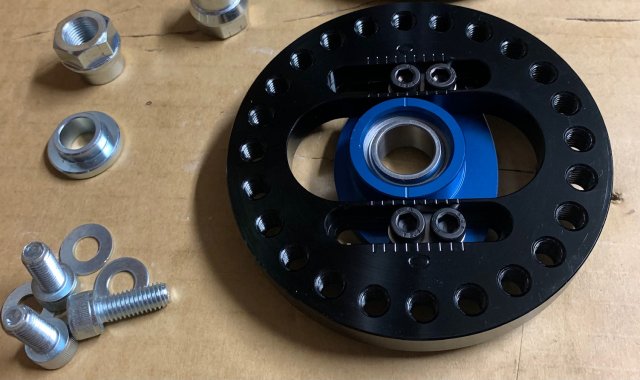

Based on what I learned, I bought CompBrake adjustable top hats and will re-install my stock camber bolts. I'm looking for about 2.25 degrees negative, and based on tire tread temps and wear, I'll adjust from there.

Can anyone provide some basic instructions on installing the top hats? The CompBrake universal diagram doesn't really help. It may be more obvious when I remove the struts.

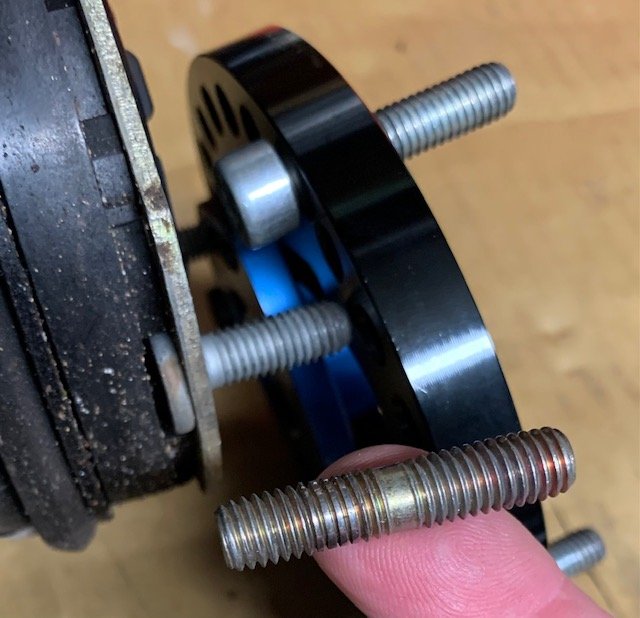

Right now, I can see how to install the center bushing and spacers, but not the three existing top studs that go through the strut tower.

Also, I can see that the top hats should be oriented so the top of the strut moves side-to-side (not front to back), but which should be the inner and outer sides of the blue siding part? It seems like I'd want the most adjustment to be inward.

Any help would be greatly appreciated.

Based on what I learned, I bought CompBrake adjustable top hats and will re-install my stock camber bolts. I'm looking for about 2.25 degrees negative, and based on tire tread temps and wear, I'll adjust from there.

Can anyone provide some basic instructions on installing the top hats? The CompBrake universal diagram doesn't really help. It may be more obvious when I remove the struts.

Right now, I can see how to install the center bushing and spacers, but not the three existing top studs that go through the strut tower.

Also, I can see that the top hats should be oriented so the top of the strut moves side-to-side (not front to back), but which should be the inner and outer sides of the blue siding part? It seems like I'd want the most adjustment to be inward.

Any help would be greatly appreciated.