Hey guys,

been a while since I've posted up here, so hope I'm not breaking any forum rules making this announcement (Mods: If I am, please let me know and I'll do whatever is required to follow the rules/signup as a vendor, although this is just an announcement and nothing is being advertised/sold yet)

since the start of 2023, we have been developing a new "Hybrid" Limited Slip Differential (offering features from both a Helical and Plate type LSD), with the latest prototypes (3rd iteration now, and hopefully final) about to go out to our testers in a couple months time. Being OEM for Honda, they are obviously our primary test partner, but as the Ford fitments are actually our 3rd best selling fitment (after Honda and BMW respectively), I thought that I would take this opportunity to announce our latest project (reason for delayed announcement is due to patent/lawyer red-tape) and see if there was anyone in this community that would be interested in assisting us with testing after we've received enough testing feedback from Honda.

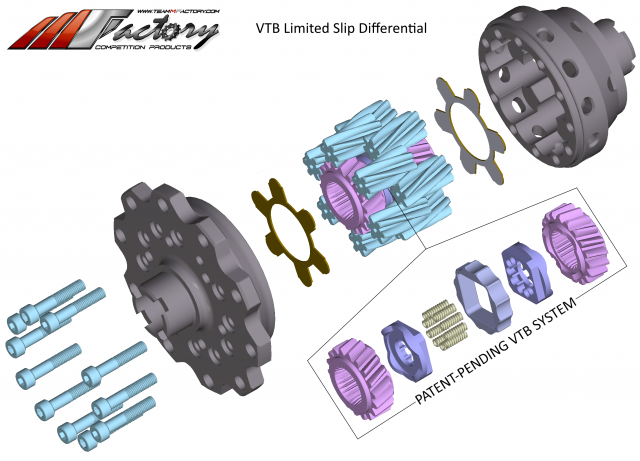

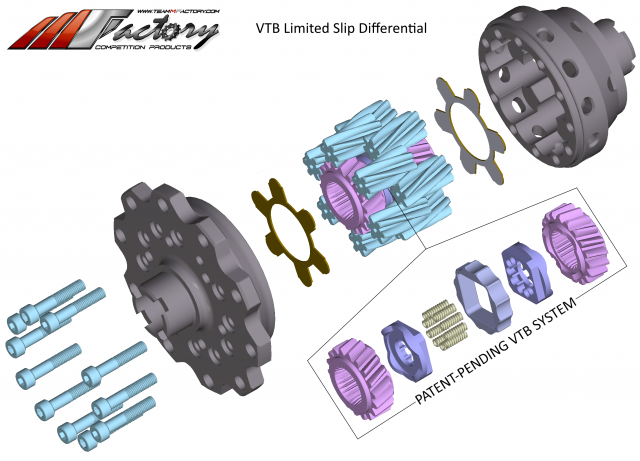

So, introducing our latest project; the MFactory VTB Limited Slip Differential (apologies for the "marketing" tone in the description that follows. It's just a direct copy & paste from our website)

////////////////////////////////////////////////////////////////

The ONLY Helical LSD on the market with hassle free variable-rate torque biasing

Through our patent-pending VTB system, users can fine tune their own Bias Ratios at the track and at no additional cost, simply by adding/removing the included coil springs. With the MFactory VTB LSD, up to 85% torque bias can be transferred to the wheel with traction! A must-have for serious circuit use. All MFactory VTB LSD's are pre-set to 75% torque bias (unless otherwise requested).

For the technically inclined:

- When driving in a straight line (or minute manoeuvring), torque will be split approximately 50/50 between the left/right axles and the internal gears of the differential will effectively be inoperational.

- If your vehicle axle speeds start to differentiate (i.e during cornering), the differential will compensate for this by biasing the axle speed of the faster spinning axle in direct proportion to the slower spinning axle. If the left axle is spinning 10% above nominal, the right axle will spin 10% slower as the left/right axles in the differential are locked together via the internal gears in opposing directions. 60% + 40% = 100%, with nominal being 50%.

- But if this is the case, then why would a vehicle that is stationary but spinning one wheel not move? This is because it is the differential housing that is providing the forward rotational movement (thus the spinning axle is rotating forward), with the stationary axle rotating backwards internally via the differential gears, effectively cancelling out the forward rotational movement of the differential housing.

- If you had 75% torque bias, this means that the stationary axle will receive 3 times the amount of torque of the spinning axle, but due to there being minimal torque transfer to the spinning axle (which has minimal or zero load, thus spinning purely on momentum), the stationary axle will not have enough torque to move the mass of the vehicle on it's own.

- This is where a pre-loaded differential comes into play. By pre-loading the internal gears of the differential, this simulates load on the axles, thus increasing the amount of torque being transferred through the differential. Once this increase in torque becomes sufficient enough to overcome the mass of the vehicle, the vehicle will start moving. With a 75% torque bias, if the spinning axle has only 20lbft of torque (which may be insufficient), the stationary axle will have 60lbft of torque going through it which is enough to start moving the vehicle.

- This applies to ALL torque-biasing differentials, however, the implementation of the pre-load system is the differentiating factor between the various LSD's on the market

Unlike all other Helical LSD's on the market, the MFactory VTB LSD uses a coil spring pre-load system, NOT Belleville spring washers. Our coil springs provide a smoother transition of load and do not lose their spring rate like spring washers do.

No-Load/One-Wheel Syndrome

The common problem with most Helical LSD's on the market is during a no-load situation (such as limited traction/ice/lifting a wheel), you may experience zero drive to the wheel with traction, depending on electronic slip intervention (e.g Traction Control).

Some of our competitors try to solve this issue by either increasing the pre-load (via Belleville spring washers) or by incorporating a mechanism to lock one axle during a no-load situation. Unfortunately, due to insufficient torque transfer, this will not provide sufficient drive to the opposing axle on a stationary vehicle. For standing-start applications (or if your vehicle is stuck on ice), it has proven to be insufficient in most cases.

With the patent-pending VTB system, which utilizes dual-pulsing cam technology, both axles are drive-locked, yet can still rotate independently of each other (unlike a Spool), similar to a regular Helical LSD. Due to being in a 100% constant state of torque-biasing, the MFactory VTB LSD will function both on & off throttle, similar to a Plate-type LSD.

The MFactory VTB LSD is the ONLY Helical LSD on the market that is a true hybrid of a Helical LSD (smoothness, noise-free, maintenance-free) and a Plate-type LSD (variable torque/load settings, increased traction under most situations).

Proprietary Friction Discs

To enhance durability and increase frictional performance, all MFactory VTB LSD's incorporate our proprietary friction discs between the gears and LSD housing. Unlike most common Helical and Plate-type LSD's on the market that lose performance over time, the MFactory VTB LSD will provide the same level of performance over the lifetime of the LSD.

Hybrid Ceramic Bearing Technology (Application Dependant)

Depending on application, the MFactory VTB LSD will be supplied with our new Hybrid Ceramic Diff Bearings. Not only are our bearings stronger and more durable, they also offer the epitome of near-zero rotational friction, minimizing parasitic drivetrain losses, thus transferring more power to the ground!

3rd Generation Design

The MFactory VTB LSD is lighter, stronger and more efficient than any other Torque-Biasing Differential on the market today!

VTB System Upgrade (Application Dependant)

Already run a regular Helical LSD and were thinking of upgrading? For select applications, we are proud to offer our patent-pending VTB System as an independent aftermarket upgrade to existing MFactory Helical LSD's. The upgrade kit includes: VTB System + VTB Gears + New Case Bolts.

////////////////////////////////////////////////////////////////

Ok, now with that out of the way, probably one of the questions that is most likely to be asked is how does this compare to the "Other" competitor on the market that also advertises a similar feature set, so I guess I'll try my best to answer it

- First and foremost, their "implementation" of the zero-load system is incomplete. What I mean by that is, only one axle is drive-locked (which side depends on the vehicle application). This means that, depending on which wheel/axle is internally drive-locked (do not confuse this with an actual "locking" differential like a Plate LSD though), the other side will not receive sufficient enough pre-load to provide the vehicle enough torque to move during standing-starts or icy conditions. This has been encountered numerous times and is a known flaw acknowledged even by themselves, contrary to their own marketing. On the track though, there usually is enough momentum for their system to work without the driver noticing it (subjective though I guess)

- Whilst the external friction discs that they use serve a similar purpose to our implementation of the friction discs (sandwiched between the helical gears and lsd housing), they also use a friction component on their zero-load system (the side that is not internally drive-locked). This is actually the part that drivers find wears out and the reason why numerous aggressive track drivers find their LSD losing the advertised zero-load "advantage" and ending up being no different from a regular Helical LSD when they lift a wheel. As both sides of our LSD are internally drive-locked and do not have a friction component to wear down, we do not have this issue. Any material is subject to wear, especially for a component that rotates around 800 times per mile on average (Imagine your brake pads rubbing against your rotors non-stop, 800 rotations per mile that you do; they are going to wear down quickly)

- Unlike their implementation though, with our LSD, drivers can actually fine-tune how much pre-load the system has (which in turn affects the torque bias). Technically, they can as well (as you can with a regular Helical LSD), but is not recommended. What I mean by this is, as our system uses coil springs, you can fine-tune the amount of pre-load without affecting functionality simply by adding/removing coil springs. As their system (as well as a regular Helical LSD) uses belleville spring washers, whilst you can increase/decrease the pre-load by changing the number of washers, this also affects the operational distance between the side gears (with coil springs, the operational distance is not affected). Too large an operational distance (less washers) and pre-load will decrease. Too small an operational distance (more washers) and you run the risk of turning the LSD into a Spool. There is also the wear issue; spring washers lose their spring rate over time due to deformation, which results in lower pre-load, decreasing performance

- We've not tested how much their system actually contributes to the overall torque bias (and I don't think anyone would deliberately remove their zero-load system to test it), but with our system, even at the minimal setting, we have a 75% torque bias (similar to our current Stage 1 Helical LSD's, which these will be superseding). Coupled with our proprietary external friction plates (well, they are still "internal" to the LSD), this ensures a longer service life with minimal gear wear

As this is not an advertisement, I cannot and will not mention pricing.

If you have any questions though (other than pricing), please feel free to ask and I'll be happy to answer

been a while since I've posted up here, so hope I'm not breaking any forum rules making this announcement (Mods: If I am, please let me know and I'll do whatever is required to follow the rules/signup as a vendor, although this is just an announcement and nothing is being advertised/sold yet)

since the start of 2023, we have been developing a new "Hybrid" Limited Slip Differential (offering features from both a Helical and Plate type LSD), with the latest prototypes (3rd iteration now, and hopefully final) about to go out to our testers in a couple months time. Being OEM for Honda, they are obviously our primary test partner, but as the Ford fitments are actually our 3rd best selling fitment (after Honda and BMW respectively), I thought that I would take this opportunity to announce our latest project (reason for delayed announcement is due to patent/lawyer red-tape) and see if there was anyone in this community that would be interested in assisting us with testing after we've received enough testing feedback from Honda.

So, introducing our latest project; the MFactory VTB Limited Slip Differential (apologies for the "marketing" tone in the description that follows. It's just a direct copy & paste from our website)

////////////////////////////////////////////////////////////////

The ONLY Helical LSD on the market with hassle free variable-rate torque biasing

Through our patent-pending VTB system, users can fine tune their own Bias Ratios at the track and at no additional cost, simply by adding/removing the included coil springs. With the MFactory VTB LSD, up to 85% torque bias can be transferred to the wheel with traction! A must-have for serious circuit use. All MFactory VTB LSD's are pre-set to 75% torque bias (unless otherwise requested).

For the technically inclined:

- When driving in a straight line (or minute manoeuvring), torque will be split approximately 50/50 between the left/right axles and the internal gears of the differential will effectively be inoperational.

- If your vehicle axle speeds start to differentiate (i.e during cornering), the differential will compensate for this by biasing the axle speed of the faster spinning axle in direct proportion to the slower spinning axle. If the left axle is spinning 10% above nominal, the right axle will spin 10% slower as the left/right axles in the differential are locked together via the internal gears in opposing directions. 60% + 40% = 100%, with nominal being 50%.

- But if this is the case, then why would a vehicle that is stationary but spinning one wheel not move? This is because it is the differential housing that is providing the forward rotational movement (thus the spinning axle is rotating forward), with the stationary axle rotating backwards internally via the differential gears, effectively cancelling out the forward rotational movement of the differential housing.

- If you had 75% torque bias, this means that the stationary axle will receive 3 times the amount of torque of the spinning axle, but due to there being minimal torque transfer to the spinning axle (which has minimal or zero load, thus spinning purely on momentum), the stationary axle will not have enough torque to move the mass of the vehicle on it's own.

- This is where a pre-loaded differential comes into play. By pre-loading the internal gears of the differential, this simulates load on the axles, thus increasing the amount of torque being transferred through the differential. Once this increase in torque becomes sufficient enough to overcome the mass of the vehicle, the vehicle will start moving. With a 75% torque bias, if the spinning axle has only 20lbft of torque (which may be insufficient), the stationary axle will have 60lbft of torque going through it which is enough to start moving the vehicle.

- This applies to ALL torque-biasing differentials, however, the implementation of the pre-load system is the differentiating factor between the various LSD's on the market

Unlike all other Helical LSD's on the market, the MFactory VTB LSD uses a coil spring pre-load system, NOT Belleville spring washers. Our coil springs provide a smoother transition of load and do not lose their spring rate like spring washers do.

No-Load/One-Wheel Syndrome

The common problem with most Helical LSD's on the market is during a no-load situation (such as limited traction/ice/lifting a wheel), you may experience zero drive to the wheel with traction, depending on electronic slip intervention (e.g Traction Control).

Some of our competitors try to solve this issue by either increasing the pre-load (via Belleville spring washers) or by incorporating a mechanism to lock one axle during a no-load situation. Unfortunately, due to insufficient torque transfer, this will not provide sufficient drive to the opposing axle on a stationary vehicle. For standing-start applications (or if your vehicle is stuck on ice), it has proven to be insufficient in most cases.

With the patent-pending VTB system, which utilizes dual-pulsing cam technology, both axles are drive-locked, yet can still rotate independently of each other (unlike a Spool), similar to a regular Helical LSD. Due to being in a 100% constant state of torque-biasing, the MFactory VTB LSD will function both on & off throttle, similar to a Plate-type LSD.

The MFactory VTB LSD is the ONLY Helical LSD on the market that is a true hybrid of a Helical LSD (smoothness, noise-free, maintenance-free) and a Plate-type LSD (variable torque/load settings, increased traction under most situations).

Proprietary Friction Discs

To enhance durability and increase frictional performance, all MFactory VTB LSD's incorporate our proprietary friction discs between the gears and LSD housing. Unlike most common Helical and Plate-type LSD's on the market that lose performance over time, the MFactory VTB LSD will provide the same level of performance over the lifetime of the LSD.

Hybrid Ceramic Bearing Technology (Application Dependant)

Depending on application, the MFactory VTB LSD will be supplied with our new Hybrid Ceramic Diff Bearings. Not only are our bearings stronger and more durable, they also offer the epitome of near-zero rotational friction, minimizing parasitic drivetrain losses, thus transferring more power to the ground!

3rd Generation Design

The MFactory VTB LSD is lighter, stronger and more efficient than any other Torque-Biasing Differential on the market today!

VTB System Upgrade (Application Dependant)

Already run a regular Helical LSD and were thinking of upgrading? For select applications, we are proud to offer our patent-pending VTB System as an independent aftermarket upgrade to existing MFactory Helical LSD's. The upgrade kit includes: VTB System + VTB Gears + New Case Bolts.

////////////////////////////////////////////////////////////////

Ok, now with that out of the way, probably one of the questions that is most likely to be asked is how does this compare to the "Other" competitor on the market that also advertises a similar feature set, so I guess I'll try my best to answer it

- First and foremost, their "implementation" of the zero-load system is incomplete. What I mean by that is, only one axle is drive-locked (which side depends on the vehicle application). This means that, depending on which wheel/axle is internally drive-locked (do not confuse this with an actual "locking" differential like a Plate LSD though), the other side will not receive sufficient enough pre-load to provide the vehicle enough torque to move during standing-starts or icy conditions. This has been encountered numerous times and is a known flaw acknowledged even by themselves, contrary to their own marketing. On the track though, there usually is enough momentum for their system to work without the driver noticing it (subjective though I guess)

- Whilst the external friction discs that they use serve a similar purpose to our implementation of the friction discs (sandwiched between the helical gears and lsd housing), they also use a friction component on their zero-load system (the side that is not internally drive-locked). This is actually the part that drivers find wears out and the reason why numerous aggressive track drivers find their LSD losing the advertised zero-load "advantage" and ending up being no different from a regular Helical LSD when they lift a wheel. As both sides of our LSD are internally drive-locked and do not have a friction component to wear down, we do not have this issue. Any material is subject to wear, especially for a component that rotates around 800 times per mile on average (Imagine your brake pads rubbing against your rotors non-stop, 800 rotations per mile that you do; they are going to wear down quickly)

- Unlike their implementation though, with our LSD, drivers can actually fine-tune how much pre-load the system has (which in turn affects the torque bias). Technically, they can as well (as you can with a regular Helical LSD), but is not recommended. What I mean by this is, as our system uses coil springs, you can fine-tune the amount of pre-load without affecting functionality simply by adding/removing coil springs. As their system (as well as a regular Helical LSD) uses belleville spring washers, whilst you can increase/decrease the pre-load by changing the number of washers, this also affects the operational distance between the side gears (with coil springs, the operational distance is not affected). Too large an operational distance (less washers) and pre-load will decrease. Too small an operational distance (more washers) and you run the risk of turning the LSD into a Spool. There is also the wear issue; spring washers lose their spring rate over time due to deformation, which results in lower pre-load, decreasing performance

- We've not tested how much their system actually contributes to the overall torque bias (and I don't think anyone would deliberately remove their zero-load system to test it), but with our system, even at the minimal setting, we have a 75% torque bias (similar to our current Stage 1 Helical LSD's, which these will be superseding). Coupled with our proprietary external friction plates (well, they are still "internal" to the LSD), this ensures a longer service life with minimal gear wear

As this is not an advertisement, I cannot and will not mention pricing.

If you have any questions though (other than pricing), please feel free to ask and I'll be happy to answer