So, like many people on this thread, I've been tossing around the ludicrous idea of wanting to convert our cars to AWD. From what I've seen, there have been a couple of Fiestas running either fully-custom racing setups; or some madman cut up a Focus RS to transplant its guts into the Fiesta. Either way, you're looking at spending many thousands of dollars in both parts and labor just to get there. Why do the Honda guys have AWD conversions for their cars all day long? Because enough of them asked for it, and a couple of companies were smart enough to build their conversions on a jig. Realistically, how many people here would pay a flat fee of, oh, $12,000, to get their cars to launch like a GT-R?

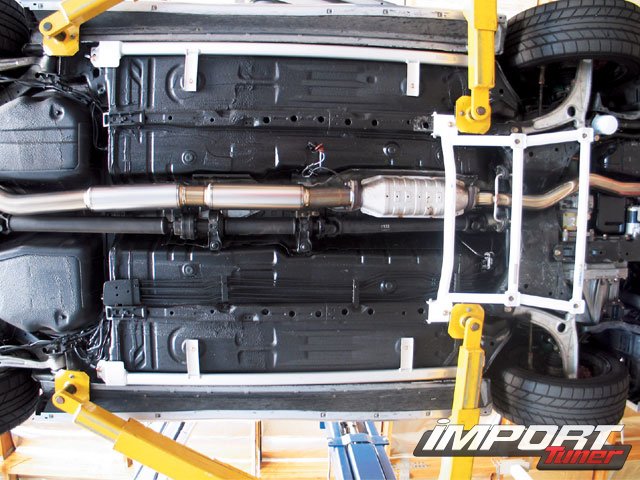

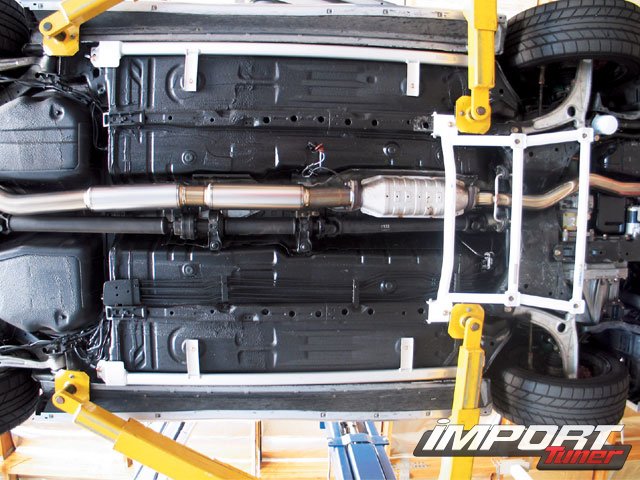

As I am in the process of buying my second car (an F13 M6), I figure that I'll keep the Fiesta around and turn it into a proper rally car. Companies like M-Sport have proven the Fiesta's worth on the dirt, but I rather not shell out $250,000 for a full-on WRC car that isn't even road-legal. Whenever I think of fast AWD cars that aren't GT-Rs or VW/Audi products, I instantly think of the Evo. They can have absolutely mind-boggling traction, and the aftermarket for them to sustain power has grown to be immense. I mean, how hard would it be to, 1) Slap in a MoTeC piggyback ECU, 2) CAD an adapter to mate the bell housing of an Evo IX transmission (part no. 2500A123), 3) Fabricate new left-side and rear motor mounts, 4) Engineer adjusted-length torque tubes and axles, 5) Use a modified version of the Evo IX's rear subframe to utilize the mounting points already on the Fiesta and fit the Evo IX's differential that doesn't utilize an AYC pump like the Evo X, and 6) Relocate the fuel cell to the trunk using a Fuel Safe Spare Tire Fuel Cell (part no. SA130-RS2)?

My interest in this only got reignited after I found a company by the name of Verkline the other day, which specializes in making custom-designed tubular subframes through CAD. I saw their subframes for the GR Yaris and was impressed to see they're being tested on the Nurburgring as we speak. Additionally, the US distributor for this Polish company is only twenty minutes away from me, and I've been thinking of emailing the company directly to see if some guys across the pond would be interested in producing a design we can come up with. I am attending a university with an immense engineering school, and I feel like throwing one of the mechanical engineers a bone, but I figured I'd ask the people of this forum to see what solutions they might come up with. We need to use parts that are plentiful and capable, so why don't we keep it JDM since our cars are glorified Mazdas?

As I am in the process of buying my second car (an F13 M6), I figure that I'll keep the Fiesta around and turn it into a proper rally car. Companies like M-Sport have proven the Fiesta's worth on the dirt, but I rather not shell out $250,000 for a full-on WRC car that isn't even road-legal. Whenever I think of fast AWD cars that aren't GT-Rs or VW/Audi products, I instantly think of the Evo. They can have absolutely mind-boggling traction, and the aftermarket for them to sustain power has grown to be immense. I mean, how hard would it be to, 1) Slap in a MoTeC piggyback ECU, 2) CAD an adapter to mate the bell housing of an Evo IX transmission (part no. 2500A123), 3) Fabricate new left-side and rear motor mounts, 4) Engineer adjusted-length torque tubes and axles, 5) Use a modified version of the Evo IX's rear subframe to utilize the mounting points already on the Fiesta and fit the Evo IX's differential that doesn't utilize an AYC pump like the Evo X, and 6) Relocate the fuel cell to the trunk using a Fuel Safe Spare Tire Fuel Cell (part no. SA130-RS2)?

My interest in this only got reignited after I found a company by the name of Verkline the other day, which specializes in making custom-designed tubular subframes through CAD. I saw their subframes for the GR Yaris and was impressed to see they're being tested on the Nurburgring as we speak. Additionally, the US distributor for this Polish company is only twenty minutes away from me, and I've been thinking of emailing the company directly to see if some guys across the pond would be interested in producing a design we can come up with. I am attending a university with an immense engineering school, and I feel like throwing one of the mechanical engineers a bone, but I figured I'd ask the people of this forum to see what solutions they might come up with. We need to use parts that are plentiful and capable, so why don't we keep it JDM since our cars are glorified Mazdas?