Long story short I got a new refurbished engine after my original had a cracking experience.

Old engine was a JTJA and the new one is a JTJB. All accesories were transferred from the old engine as the new one is a short engine(block and head). It has all new OE bearings, valves, springs, gaskets, timing belt and waterpump, everything. My mechanic put it in, but ended up timing the crank wrong(it wouldn't start) and I had Ford time it properly. Starts every time no problem.

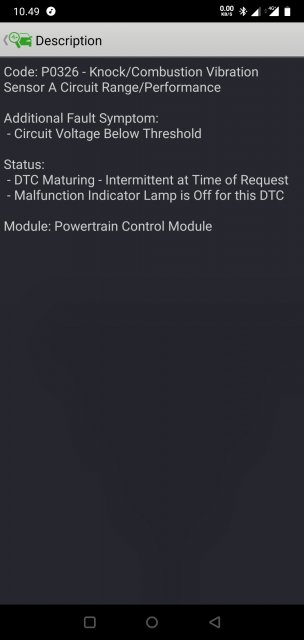

The problem now is, after around 20 minutes of driving it throws code P0326. Attached is a screendump from Forscan lite(Android app).

It puts the car in a sort of limp mode with no CEL. I can on the go remove the error and it goes out of limp mode for about 30sec and the error comes back.

It seems to only happen when it's warm but have had an instance where it would do it cold when stomping the brake in a roundabout(a truck pulled out with no real room).

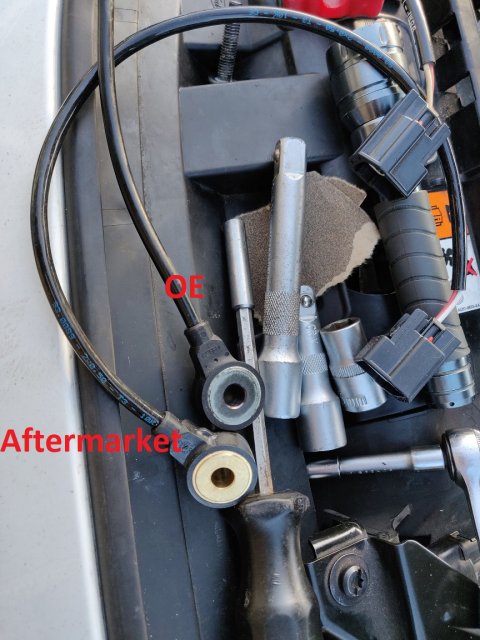

So far I've tried removing the knock sensors(both sides) and sanding the block where it contacts and cleaning both the sensor and block with brake cleaner. The problem persists.

I had it in at Ford and they said, maybe fuel pump but since they couldn't read the error(I don't know why) they couldn't diagnose it properly and referred me to a tuner. They said it fet like it didn't get enough fuel.

I checked mode:6 and it doesn't register misfires. And it doesn't feel like it misfires.

The boost doesn't want to go past 10-12psi in this limp mode.

My fuel pressure maxes out at 2200-2300psi, don't know if this is normal or not. I have a brand new HPFP and cam follower tappet ready to install.

My setup:

Block is modded with the Pumaspeed shims.

PumaSpeed X47R

Turbosmart IWG75(tune+ version)

GFB Diverter valve

Brand new Denso ITV20 spark plugs(same temp as stock)

Mishimoto OCC

R-Sport Pro 400 full size intercooler

Old engine was a JTJA and the new one is a JTJB. All accesories were transferred from the old engine as the new one is a short engine(block and head). It has all new OE bearings, valves, springs, gaskets, timing belt and waterpump, everything. My mechanic put it in, but ended up timing the crank wrong(it wouldn't start) and I had Ford time it properly. Starts every time no problem.

The problem now is, after around 20 minutes of driving it throws code P0326. Attached is a screendump from Forscan lite(Android app).

It puts the car in a sort of limp mode with no CEL. I can on the go remove the error and it goes out of limp mode for about 30sec and the error comes back.

It seems to only happen when it's warm but have had an instance where it would do it cold when stomping the brake in a roundabout(a truck pulled out with no real room).

So far I've tried removing the knock sensors(both sides) and sanding the block where it contacts and cleaning both the sensor and block with brake cleaner. The problem persists.

I had it in at Ford and they said, maybe fuel pump but since they couldn't read the error(I don't know why) they couldn't diagnose it properly and referred me to a tuner. They said it fet like it didn't get enough fuel.

I checked mode:6 and it doesn't register misfires. And it doesn't feel like it misfires.

The boost doesn't want to go past 10-12psi in this limp mode.

My fuel pressure maxes out at 2200-2300psi, don't know if this is normal or not. I have a brand new HPFP and cam follower tappet ready to install.

My setup:

Block is modded with the Pumaspeed shims.

PumaSpeed X47R

Turbosmart IWG75(tune+ version)

GFB Diverter valve

Brand new Denso ITV20 spark plugs(same temp as stock)

Mishimoto OCC

R-Sport Pro 400 full size intercooler

Attachments

-

245.9 KB Views: 12