Hey guys,

Recently realized my boost levels were lower than usual, and I was hearing the telltale hiss from my engine bay while driving, so I had a suspicion than I had an exhaust leak up front. I’m running an S280 with a Whoosh DP, and replaced all of the factory manifold studs and nuts with brand new ones when I installed the turbo. It had been a while since I’d tightened everything up.

Under the car I found that one of my turbo to downpipe studs had backed itself out and was lost forever on a road somewhere, along with the nut. Assuming it was the obvious culprit, I replaced this with some nice titanium hardware but the pesky hiss persisted. So I checked the nuts/studs at the manifold to head and the manifold to turbo flange. Found all 4 lateral-most nuts on the head-manifold studs were a bit loose, so I snugged em up.

Of the manifold to turbo flange studs, one was still fine, one was a bit loose, and one was VERY loose, on its way to joining its buddy on a highway shoulder. Snugged these up too, and lo and behold: no more hiss, boost levels back to normal, car sounding and feeling like it hasn’t in a while!

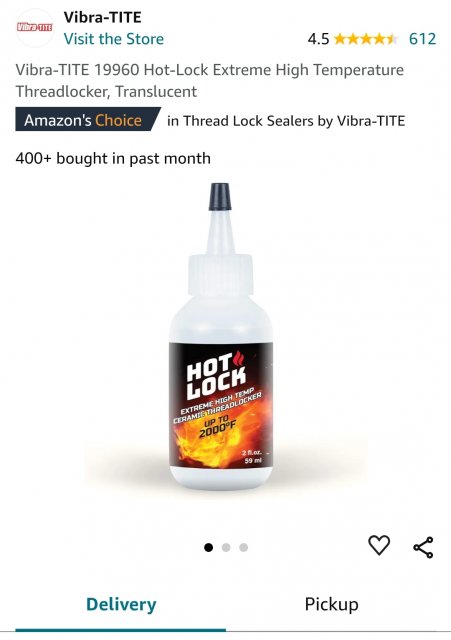

Which leads me to the obvious question…how do I prevent this happening again? I don’t want to keep slowly losing power and dealing with loose hardware that I have to address once every few months. Obviously using loctite on exhaust hardware is insanity, but given the seeming tendency of some of these studs/nuts to vibrate loose, it almost seems plausible.

What are yall doing for your own cars? Locking hardware kits? Tips/tricks?

Recently realized my boost levels were lower than usual, and I was hearing the telltale hiss from my engine bay while driving, so I had a suspicion than I had an exhaust leak up front. I’m running an S280 with a Whoosh DP, and replaced all of the factory manifold studs and nuts with brand new ones when I installed the turbo. It had been a while since I’d tightened everything up.

Under the car I found that one of my turbo to downpipe studs had backed itself out and was lost forever on a road somewhere, along with the nut. Assuming it was the obvious culprit, I replaced this with some nice titanium hardware but the pesky hiss persisted. So I checked the nuts/studs at the manifold to head and the manifold to turbo flange. Found all 4 lateral-most nuts on the head-manifold studs were a bit loose, so I snugged em up.

Of the manifold to turbo flange studs, one was still fine, one was a bit loose, and one was VERY loose, on its way to joining its buddy on a highway shoulder. Snugged these up too, and lo and behold: no more hiss, boost levels back to normal, car sounding and feeling like it hasn’t in a while!

Which leads me to the obvious question…how do I prevent this happening again? I don’t want to keep slowly losing power and dealing with loose hardware that I have to address once every few months. Obviously using loctite on exhaust hardware is insanity, but given the seeming tendency of some of these studs/nuts to vibrate loose, it almost seems plausible.

What are yall doing for your own cars? Locking hardware kits? Tips/tricks?