What did you do to your Fiesta ST today ?

No....

I wasn't aware that was something that needed to be done. I followed this: https://www.fiestastforum.com/threa...eel-braided-brake-hoses-install-review.25513/

If there's a better how-to I'm all ears, this is the first time I've ever done brakes so...

I wasn't aware that was something that needed to be done. I followed this: https://www.fiestastforum.com/threa...eel-braided-brake-hoses-install-review.25513/

If there's a better how-to I'm all ears, this is the first time I've ever done brakes so...

The banjo is installed with a new washer. You tighten the banjo until the washer feels crushed & wont turn anymore. Tap the banjo head with a hammer & the banjo will tighten a little more, creating a solid seal.

Nowhere in my instructions did I mention torquing the bolt & then doing this. It’s not a trick. It’s an order of operations.

That said, although I have never had a printed shop manual for the modern Fiesta, I had one for my 1978 Fiesta, I have one for my 1994 Miata, and I had one for my 1970 F100. And I did brakes on all those cars. None of the manuals said to hit the bolt with a hammer.

My search revealed these instructions, which put optionally tapping the bolt after initial torquing.

Key Procedures for Tightening Banjo Bolts:

- Use New Washers: Always replace copper or steel crush washers to ensure a proper seal.

- Check Fitting: Ensure the washer is placed on both sides of the banjo fitting (between the bolt head and fitting, and fitting and component).

- Hand Tighten First: Thread the bolt by hand to avoid cross-threading.

- Torque Specification: Tighten to the manufacturer's spec. For many automotive brake applications, this is around

25−3025 minus 30

ft-lbs. Specific recommendations include

96−12096 minus 120

in-lbs (do not exceed 144 in-lbs) or

5−85 minus 8

ft-lbs for some specialized applications. - The "Tap" Trick: After snugging the bolt, a light tap with a hammer on the hex head can help properly seat the crush washer for a better seal.

- Inspect for Leaks: Check for leaks after the initial installation. Over-tightening can break the bolt, so it is better to tighten gradually.

- Bleed the System: If the bolt is part of a hydraulic system (brakes/clutch), bleed the system afterward to remove any air introduced during the process.

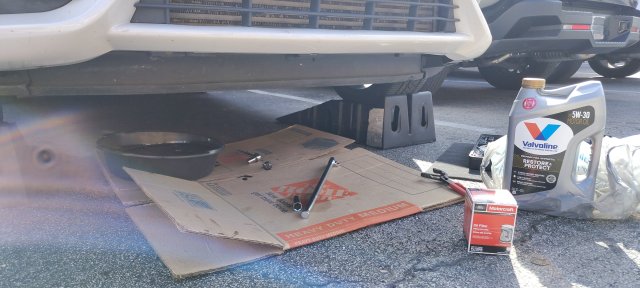

And so, another oil change has come and gone. Waited until the cold snap left Florida to pull this one off. Also went big filter. Turns out my buddy with a Crown Vic bought an extra FL400s and just gave it to me.

But while priming the engine I nearly killed the battery again, so time to use that tender I bought again, left it on the juice for 10 hours - charger said it was charged by the time I woke up at night to go to work.

I guess it's time to start budgeting a new battery. This one is from 2021 and it's obvious that it's on borrowed time.

But while priming the engine I nearly killed the battery again, so time to use that tender I bought again, left it on the juice for 10 hours - charger said it was charged by the time I woke up at night to go to work.

I guess it's time to start budgeting a new battery. This one is from 2021 and it's obvious that it's on borrowed time.

Similar threads

-

I did a Fiesta ST Timing Belt, Here are my observations (and problems)

- Started by rallyrabbit

- Replies: 40

-

-

What did you do instead of working on your Fiesta ST today?

- Started by Chaski

- Replies: 257

-

2018 Fiesta ST possible rally build candidate

- Started by Northwest

- Replies: 10

-

Did you know your Fiesta ST could.....("secret" features thread)

- Started by jeff

- Replies: 173

-

-

-

-

Which Fiesta ST Intercooler did you choose?

- Started by rooSTer

- Replies: 522

-

Which Fiesta ST Exhaust System did you purchase?

- Started by ATXFiST

- Replies: 398