-

Sign Up! To view all forums and unlock additional cool features

Welcome to the #1 Fiesta ST Forum and Fiesta ST community dedicated to Fiesta ST owners and enthusiasts. Register for an account, it's free and it's easy, so don't hesitate to join the Fiesta ST Forum today!

Really Should Stop Modifying my Daily Driver into a Track Car

- Thread starter Fusion Works

- Start date

Thread Starter

#205

Thread Starter

#205

I finally bought my first welder last week. No more mooching off my buddy or driving to his shop with 10mil other humans to fix or build stuff.

Now you need to build a welder cart. Hope you got a gas bottle to go with it. Flux core sucks.

…This is the problem of most beginning welders, they are too cold.

Flux core sucks.

Flux core sucks.

Grind, sand, prep with acetone. Then do it again. You’re probably still not clean enough.

And flux core doesn’t suck. Dirty metal makes it suck. Mig is great for welding upside down. But if you want to WELD, use ac/dc tig.

Thread Starter

#208

Thread Starter

#208

Flux core sucks, fight me . (unless you are building a bridge or welding a structure in a hurricane) Dual shield is really cool tech though. For most DIY guys a MIG with gas can make beautiful strong welds. Getting the machine and the operator setup correctly is worth it.

. (unless you are building a bridge or welding a structure in a hurricane) Dual shield is really cool tech though. For most DIY guys a MIG with gas can make beautiful strong welds. Getting the machine and the operator setup correctly is worth it.

Yes Prep is another one I see not even amateurs fail at. I love my blast cabinet. It gets me clean bare metal with a quickness. Acid tanks are good for mild steel. Cleans off rust and mill scale well.

Love me some TIG, but its time consuming for somethings. Roll cages with TIG SUCKS. I tend to MIG tack exhaust systems, and carry them to the bench for finishing. (I only do stainless exhausts now).

Yes Prep is another one I see not even amateurs fail at. I love my blast cabinet. It gets me clean bare metal with a quickness. Acid tanks are good for mild steel. Cleans off rust and mill scale well.

Love me some TIG, but its time consuming for somethings. Roll cages with TIG SUCKS. I tend to MIG tack exhaust systems, and carry them to the bench for finishing. (I only do stainless exhausts now).

Roll cages with TIG SUCKS. I tend to MIG tack exhaust systems, and carry them to the bench for finishing. (I only do stainless exhausts now).

If you have a good welder with the right settings available, some new wire, flux core can burn through the big projects fast. Fussy car stuff that needs speed is solid core. Fussy car stuff that you want to spend a day on? Tig.

It’s like manual milling and CNC. Some stuff you just need to blitz on the manual real quick. Other stuff needs coding.

Sold my mig when I went all stainless on the cars. Bought a fist with mild steel pipes and I needed to bust out the Oxy on it one day. Not fun. Considering a cheap mig again now.

Makin’ bacon

Thread Starter

#213

Thread Starter

#213

I am happyish with the aero, I think there is some more to be gained with tuning. The OEM flat panels do a decent job with the floor aero and my panel covering the rear beam cleaned that area up. A rear diffuser would be the best way to clean up the under hatch area. Rules preclude a full flat floor and as this is still a street car, I am not interested in going that route. My front splitter goes back to the front axle centerline per the rules. I keep debating a tray behind the axle centerline that will replace my tunnel cross bracing with a flat plate of aluminum.

Thread Starter

#214

Thread Starter

#214

FINALLY. After multiple tries at getting the damn trans case to seal I gave up and ordered another case from FERD. Seems like even getting a pressure proof weld joint, when the bearing went in something opened back up and fluid starting leaking out after I installed the transmission. Talk about soul crushing.

Now the car is back on the ground and I am finally driving my car again. Its so nice. Got the shifter properly adjusted and its so money. Love driving it with the Coolerwerx. Does anyone else have this issue with the dog bone rubbing on the side of the console trim?

Now the car is back on the ground and I am finally driving my car again. Its so nice. Got the shifter properly adjusted and its so money. Love driving it with the Coolerwerx. Does anyone else have this issue with the dog bone rubbing on the side of the console trim?

Attachments

-

993.1 KB Views: 1

Thread Starter

#216

Thread Starter

#216

Also swapped out my old RT660s for a freshish set of Maxxis VR1s. These are the tires I am using for my street wheels and I have a set on my track wheels. I bought them lasst July when Maxxis had a big sale. Think they were 350$ for a set of four 215/40-17. Great for going going back and forth to work. HAHA

Also made a change to the rear shocks and all the springs. The revalved dampers have a TON of rebound compared to anything off the shelf and I think I got the rear dampers wrong on the low speed rebound. The car was almost un drivable on the street because of the rebound. I also wonder if that much rebound was causing the tied down feel of the rear axle on track. No problem. I have a new set of track dampers in the work. I softened the springs from 250/250 to 180/162. I am kicking around some options for street valving, but may be able to work with off the shelf B6/B8 valving on the rear. Obviously my front struts being custom will require something different, but the current dampers use an insert so off the shelf Bilstein B6/B8 front dampers won't replace that. Now it rides almost like a Cadillac. HAHA.

Also made a change to the rear shocks and all the springs. The revalved dampers have a TON of rebound compared to anything off the shelf and I think I got the rear dampers wrong on the low speed rebound. The car was almost un drivable on the street because of the rebound. I also wonder if that much rebound was causing the tied down feel of the rear axle on track. No problem. I have a new set of track dampers in the work. I softened the springs from 250/250 to 180/162. I am kicking around some options for street valving, but may be able to work with off the shelf B6/B8 valving on the rear. Obviously my front struts being custom will require something different, but the current dampers use an insert so off the shelf Bilstein B6/B8 front dampers won't replace that. Now it rides almost like a Cadillac. HAHA.

Thread Starter

#217

Thread Starter

#217

WOW, been awhile since I have updated this thread. Not a whole lot other than playing with aero and enjoying driving the car over the last year. Got a track day at Barber later this month so of course that requires a whole new suspension and updated splitter cuz I am a dumbass.

New front camber/caster plates with a Spherical bearing

A new spring perch for the top of a 2.5in race spring. I made adapters for my previous setup to use the stock top hat.

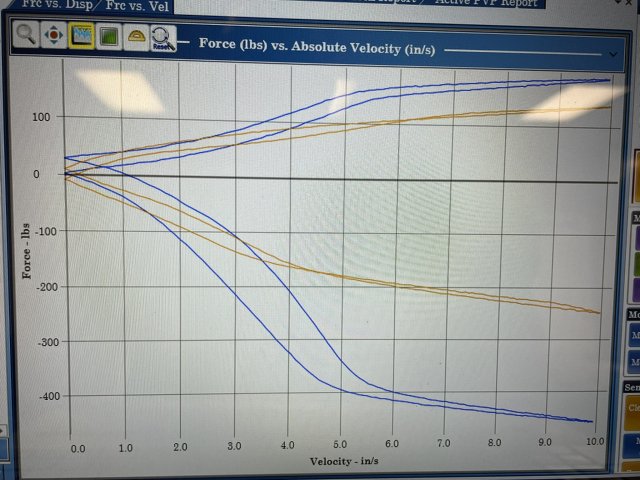

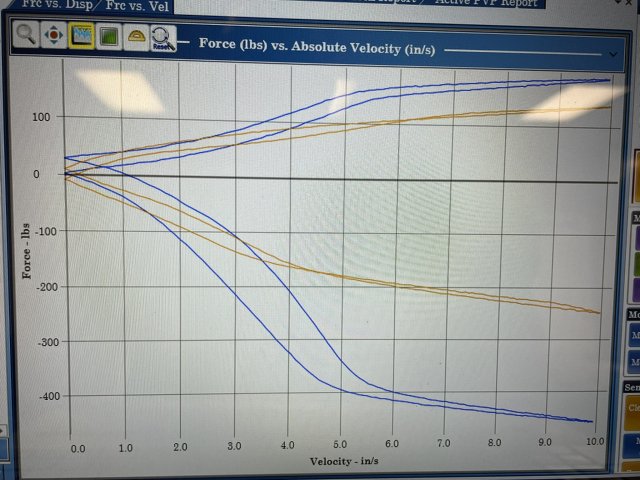

I built some rear shocks before that I never got to test so I am going to try them out after the last round of dampers I had. The had too much rebound and the car wouldn't loosen up like I wanted on corner entry. I replaced them with some plain old stock dampers and the car instantly loosened up. The new dampers are indicated by the orange trace and the old set by the blue trace.

Modified my old track splitter for street/track use. Trimmed it down about 1in and added a reinforcement across the front edge to eliminate the flex I was seeing before. I also bent up some simple diffusers t test as well.

New front camber/caster plates with a Spherical bearing

A new spring perch for the top of a 2.5in race spring. I made adapters for my previous setup to use the stock top hat.

I built some rear shocks before that I never got to test so I am going to try them out after the last round of dampers I had. The had too much rebound and the car wouldn't loosen up like I wanted on corner entry. I replaced them with some plain old stock dampers and the car instantly loosened up. The new dampers are indicated by the orange trace and the old set by the blue trace.

Modified my old track splitter for street/track use. Trimmed it down about 1in and added a reinforcement across the front edge to eliminate the flex I was seeing before. I also bent up some simple diffusers t test as well.

Similar threads

-

How critical is setting the preload really

- Started by unspankable

- Replies: 7

-

I'm in a spot of trouble, could really use some advice...

- Started by ORANGEST

- Replies: 4

-

How thin is the paint really?

- Started by BleehbleBlahble

- Replies: 10

-

Can’t figure out Really cool feature! How to change climate control via voice command

- Started by Stkid93

- Replies: 0

-

How much does brake rotor slot direction really matter?

- Started by Jabbit

- Replies: 9

-

Vega wing and risers really change the car

- Started by Whenchilling

- Replies: 11

-

Code P219a- really the 02 sensor, or something else?

- Started by mdirks

- Replies: 6

-

Best rotor pad combo for daily driver in really hot climate.

- Started by GreenenvyFiST

- Replies: 39

-

-